Wholesale Cutting Discs from China Manufacturer |

Bulk Supply for Distributors

Certificates

Our abrasive tools factory meets stringent global safety standards.

What cut-off wheels are used for

Cut-off wheels, also known as cutting discs, are bonded abrasive tools designed for straight-line cutting of metal and other hard materials. They are commonly used on angle grinders and stationary cutting machines to cut steel profiles, pipes, sheets, and structural components.

Unlike grinding wheels, which are intended to remove material and shape surfaces, cut-off wheels are optimized for penetration speed, cutting stability, and minimal material loss. Their performance directly affects cutting efficiency, heat generation, burr formation, and operator safety.

From a manufacturing perspective, a cut-off wheel is not a simple consumable. It is a composite product whose behavior depends on abrasive grain selection, bond formulation, fiberglass reinforcement, pressing method, and curing control. Small changes in any of these factors can lead to large differences in cutting feel, wheel life, and breakage risk.

This page explains how cut-off wheels are made, how different designs behave in real use, and how to choose the right product based on material, application, and operating conditions.

Common types of cut-off wheels

Flat cut-off wheels

Flat cut-off wheels, often referred to as Type 1 or T41, are the most widely used cutting discs. They have a straight profile and are designed for perpendicular cutting.

They are commonly used for:

-

Carbon steel bars and profiles

-

Pipes and tubes

-

Sheet metal

-

General fabrication work

Flat wheels provide good control and consistent cutting depth, especially when the tool is kept square to the workpiece.

Depressed center cut-off wheels

Depressed center cut-off wheels, sometimes identified as T42, have a recessed hub area. This design allows better clearance between the grinder body and the workpiece.

They are typically selected when:

-

Slight angular cutting is required

-

Tool clearance is limited

-

Operators prefer improved handling

Super thin cut-off wheels

Super thin cut-off wheels, typically 1.0 mm or 1.2 mm thick, are designed for high-speed cutting with low cutting resistance.

In practice, thinner wheels offer:

-

Faster cutting speed

-

Reduced heat input

-

Cleaner cut edges

-

Lower burr formation

They are widely used for stainless steel and thin-wall materials, where excessive heat can cause discoloration or deformation.

However, thin wheels also place higher demands on manufacturing consistency and reinforcement design. This is one of the reasons why not all thin cut-off wheels perform equally in real-world use.

Large diameter cut-off wheels

Large diameter cut-off wheels, generally above 300 mm, are used on stationary cutting machines or heavy-duty equipment. These wheels require stricter control of balance, density, and reinforcement due to higher peripheral speeds and cutting loads.

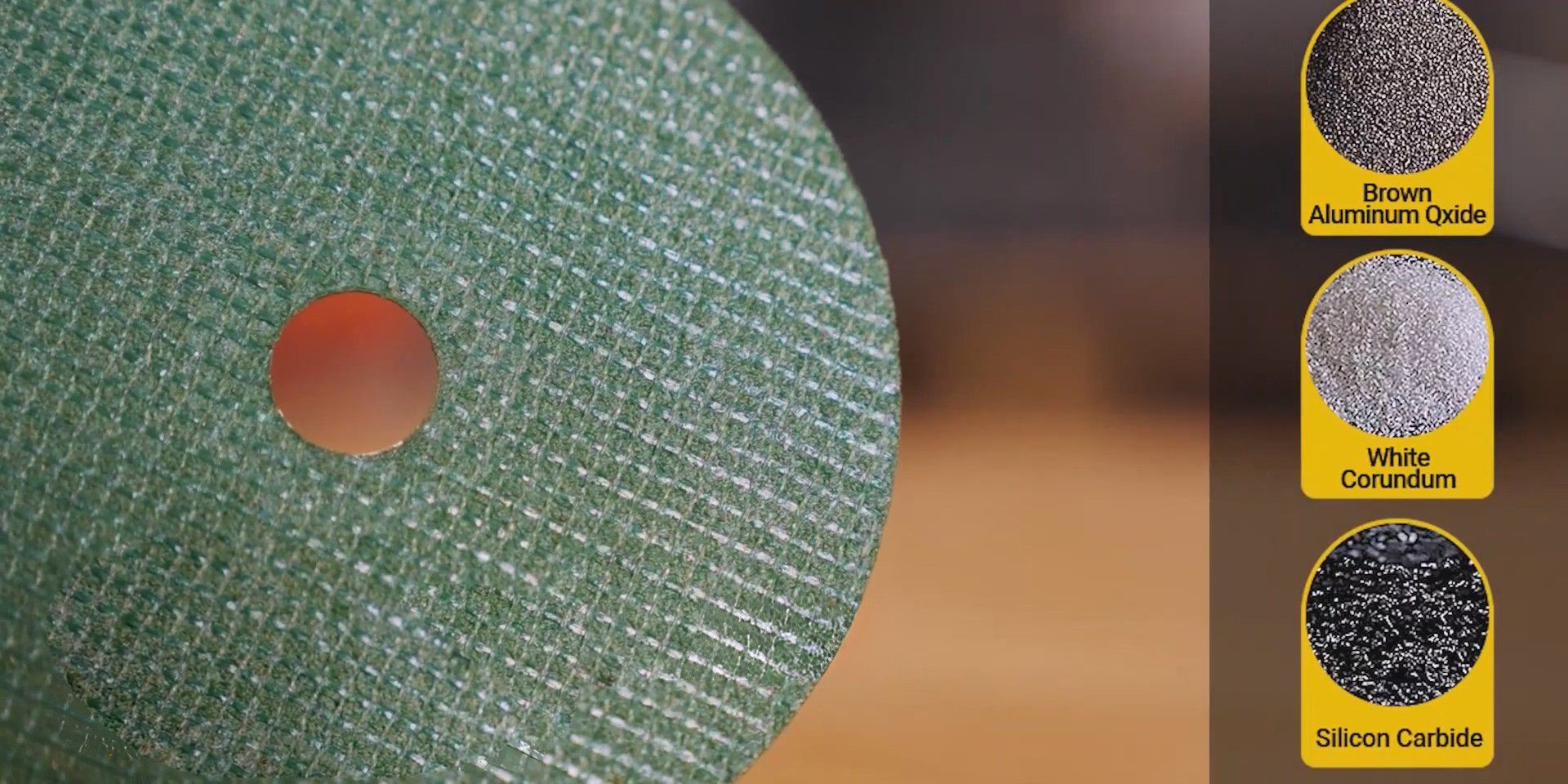

Abrasive materials and their behavior in cutting

Aluminum oxide and white aluminum oxide

Aluminum oxide is the most commonly used abrasive for metal cutting. It offers stable performance and good durability for carbon steel and general metal applications.

White aluminum oxide has higher purity and friability. In stainless steel cutting, it fractures more easily, exposing new sharp edges and reducing heat buildup. This is why white aluminum oxide is often preferred for inox applications.

Zirconia alumina

Zirconia abrasives are tougher and more impact-resistant. They are often promoted as a premium option, but in real production and usage, zirconia is not always the best choice.

In applications with sufficient cutting pressure and stable operation, zirconia provides long service life. However, in high-speed, low-pressure cutting, an optimized aluminum oxide formulation can perform equally well or better, especially in terms of cutting stability and cost efficiency.

In manufacturing, abrasive selection is not about choosing the most expensive grain, but about matching grain behavior to the actual cutting conditions.

Silicon carbide and ceramic abrasives

Silicon carbide is sharp and brittle, making it suitable for non-ferrous metals and certain hard or brittle materials.

Ceramic abrasives represent advanced grain technology with microcrystalline structures. They offer aggressive cutting and long life in demanding industrial applications, but require precise bond control and are typically used in higher-end products.

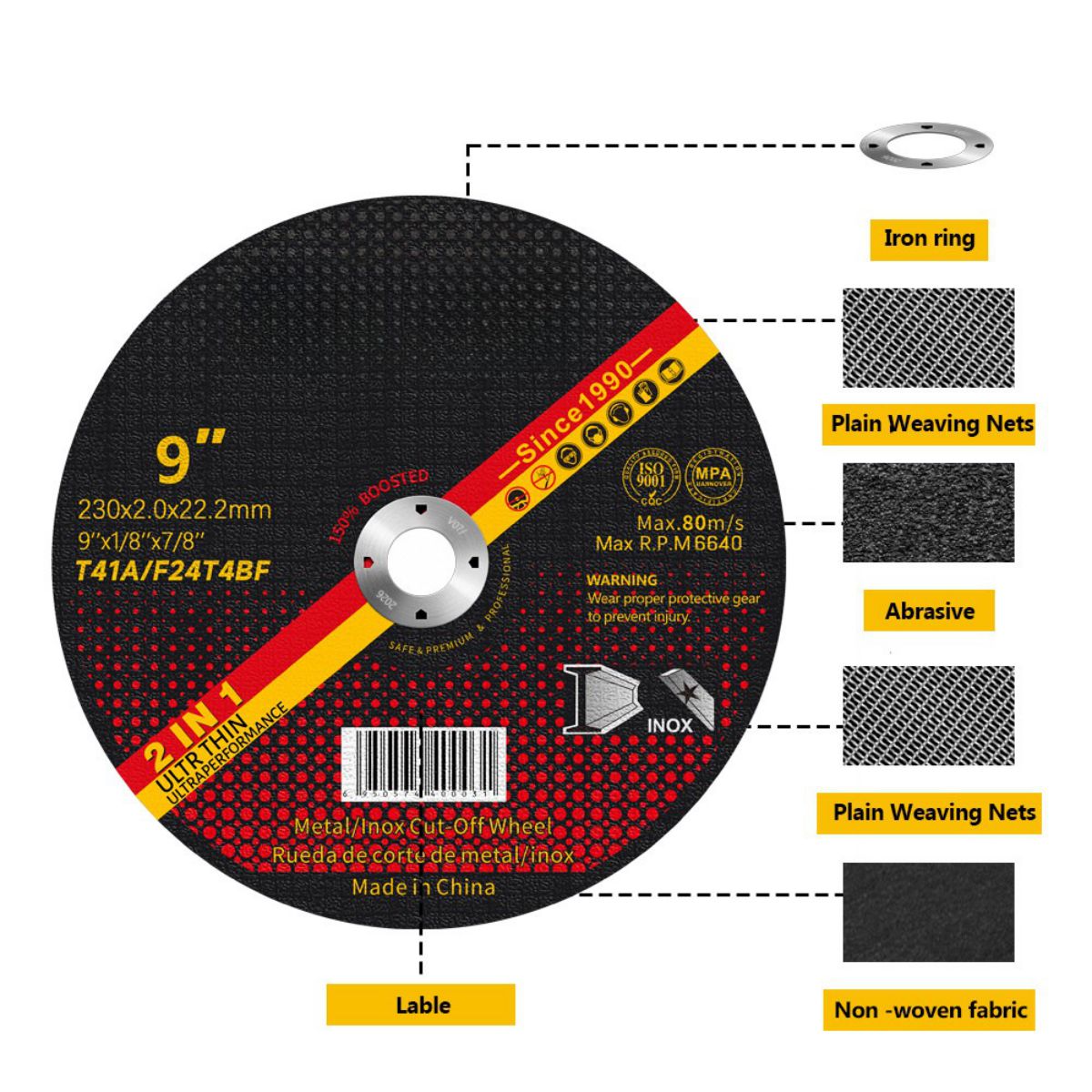

Bonding system and fiberglass reinforcement

Most cut-off wheels for metal cutting use resin bonding systems. Resin bonds provide flexibility, shock resistance, and reliable cutting performance at high speeds.

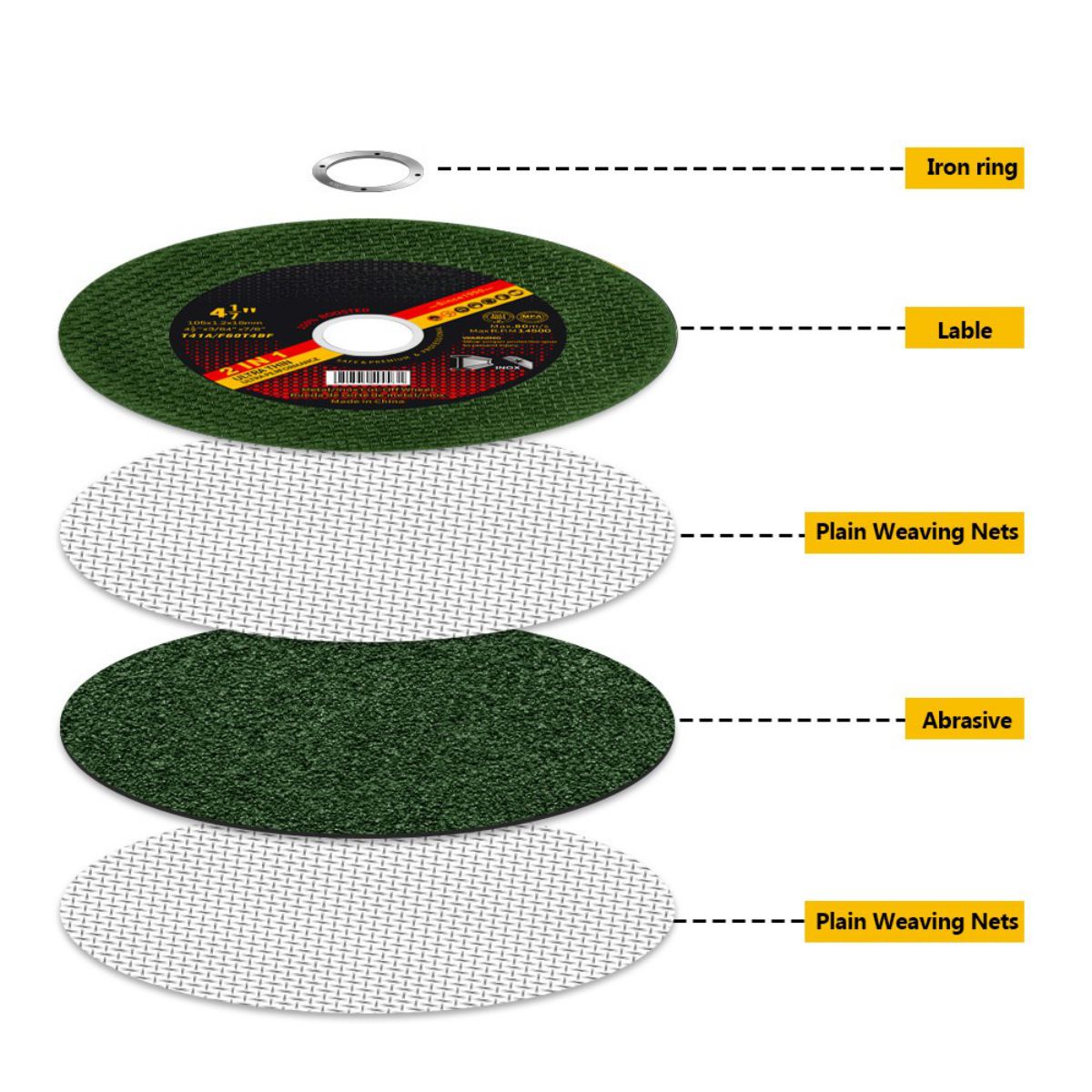

Reinforcement is critical for safety and stability. A commonly used industrial structure is the 2+1 fiberglass sandwich reinforcement, where two mesh layers are placed near the surfaces and one additional layer is embedded internally.

This structure improves:

-

Burst resistance

-

Edge stability

-

Cutting safety at high RPM

For thin cut-off wheels, reinforcement design plays a decisive role. Insufficient reinforcement often leads to edge cracking or sudden breakage, even when the abrasive quality appears acceptable.

Manufacturing processes and real production considerations

Pressing methods

Cut-off wheels can be produced using cold pressing, hot pressing, or semi-hot pressing.

Cold pressing is widely used for standard products and offers good dimensional control. However, in ultra-thin specifications, cold pressing alone may result in density variation at the wheel edge.

In actual production, semi-hot or hot pressing is often applied selectively to thin cut-off wheels to improve density uniformity and edge strength. Although this increases manufacturing cost, it significantly reduces the risk of edge cracking during high-speed cutting.

This is a practical example where manufacturing decisions are driven by real performance, not by production efficiency alone.

Curing and bond stabilization

After pressing, cut-off wheels undergo a curing process to polymerize the resin bond. In professional manufacturing, curing is performed within industry-accepted temperature and time ranges validated by resin chemistry and wheel thickness.

Proper curing ensures:

-

Stable mechanical strength

-

Consistent cutting behavior

-

Reliable shelf life

Over-curing can make a wheel too brittle, while under-curing can lead to soft bonds and premature wear. This balance is one of the most sensitive aspects of cut-off wheel production.

Quality control and testing

Professional manufacturers implement multiple quality control steps, including:

-

Dimensional inspection

-

Visual inspection for surface defects

-

Speed and burst testing in accordance with EN12413

-

Balance checks for larger diameters

These procedures are essential to ensure safety and consistency, especially for export markets.

Typical applications in different markets

Cut-off wheels are used across a wide range of industries, including metal fabrication, construction, maintenance, and industrial manufacturing.

In export markets such as Southeast Asia, South America, and the Middle East, environmental conditions and usage habits vary significantly. Higher ambient temperatures and longer continuous cutting cycles place greater stress on bond systems and reinforcement structures.

In such environments, manufacturing stability and formulation consistency often matter more than nominal abrasive grade.

When a cut-off wheel is not the right choice

Thin cut-off wheels are often selected for speed, but they are not suitable for every application.

For example:

-

Heavy side pressure can cause thin wheels to flex and crack

-

Unstable workpieces increase breakage risk

-

Using a cut-off wheel for grinding is unsafe and incorrect

In some cases, a slightly thicker wheel results in lower overall cost due to improved stability, longer service life, and safer operation.

Professional suppliers should clearly communicate these limitations instead of promoting a single solution for all scenarios.

How to choose the right cut-off wheel

Selecting a cut-off wheel should start with the material being cut:

-

Carbon steel generally works well with aluminum oxide or zirconia

-

Stainless steel benefits from white aluminum oxide or optimized zirconia formulations

Thickness selection is equally important. 1.0 mm and 1.2 mm wheels are ideal for precision cutting and reduced heat input, while thicker wheels may be more appropriate for rough or unstable conditions.

Machine compatibility, operating speed, and safety requirements must always be considered.

OEM customization and manufacturing capability

Professional cut-off wheel manufacturers typically offer OEM and customization options, including:

-

Abrasive formulation adjustment

-

Wheel thickness and hardness control

-

Arbor size customization

-

Label and packaging design

-

Private branding

However, responsible manufacturers also define clear technical boundaries. Certain combinations of thickness, diameter, and operating speed may be rejected if they compromise safety or performance.

This balance between customization and technical responsibility is an important indicator of manufacturing professionalism.

Industry standards and compliance

High-quality cut-off wheels are produced in compliance with recognized safety standards such as EN12413 for bonded abrasives. Compliance ensures that products meet minimum safety requirements for burst resistance and operational stability.

Standards compliance should be viewed as a baseline, not as a substitute for good manufacturing practice.

Cut-off wheels are engineered products that require careful material selection, controlled manufacturing processes, and strict quality management. Their performance in real-world use is determined not by a single factor, but by the combined effect of design decisions made during production.

For buyers and distributors, understanding these fundamentals helps in selecting reliable products and evaluating suppliers beyond surface-level specifications.

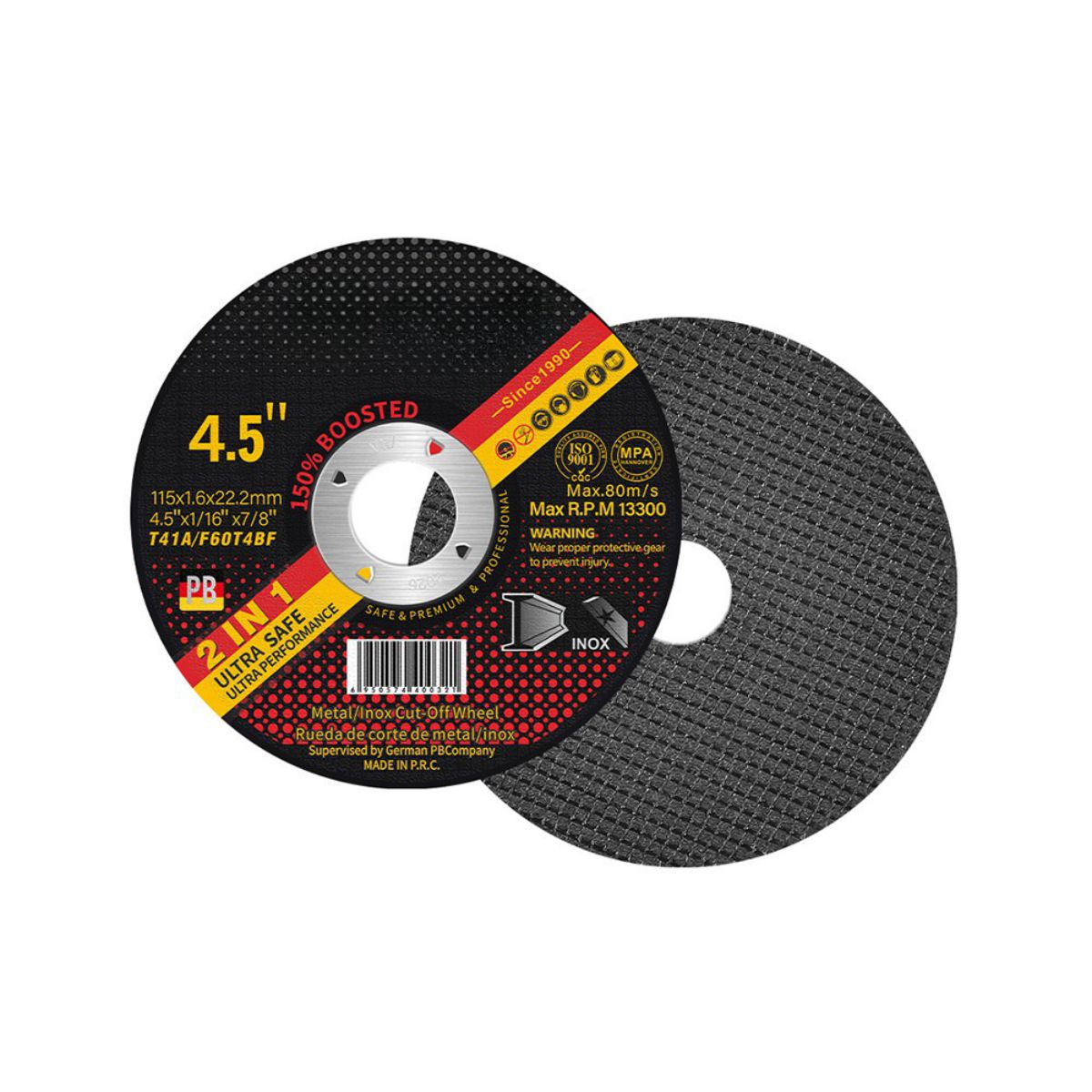

Why Choose Our Abrasive Cutting Wheels and Grinding Wheels for Wholesale

We offer a wide range of cutting discs for efficient cutting of different materials. Each cutting disc is strictly quality controlled and suitable for all types of angle grinders to meet industrial durability requirements.

Special Line SG-PLUS

Applicable materials: Steel

Binder type: Resin bond, reinforced fiber

Abrasive type: Aluminium Oxide A

Features:

-

Super hardness T grade

-

Extremely high cutting performance and long service life

-

Suitable for cutting thin plates, profiles, solid metal materials

-

Maximum speed up to 15,200 RPM

Recommended applications:

-

Fast cutting: 1.6mm / 2.0mm

-

Versatile cutting: 2.5mm

-

High stability cutting: 3.0mm

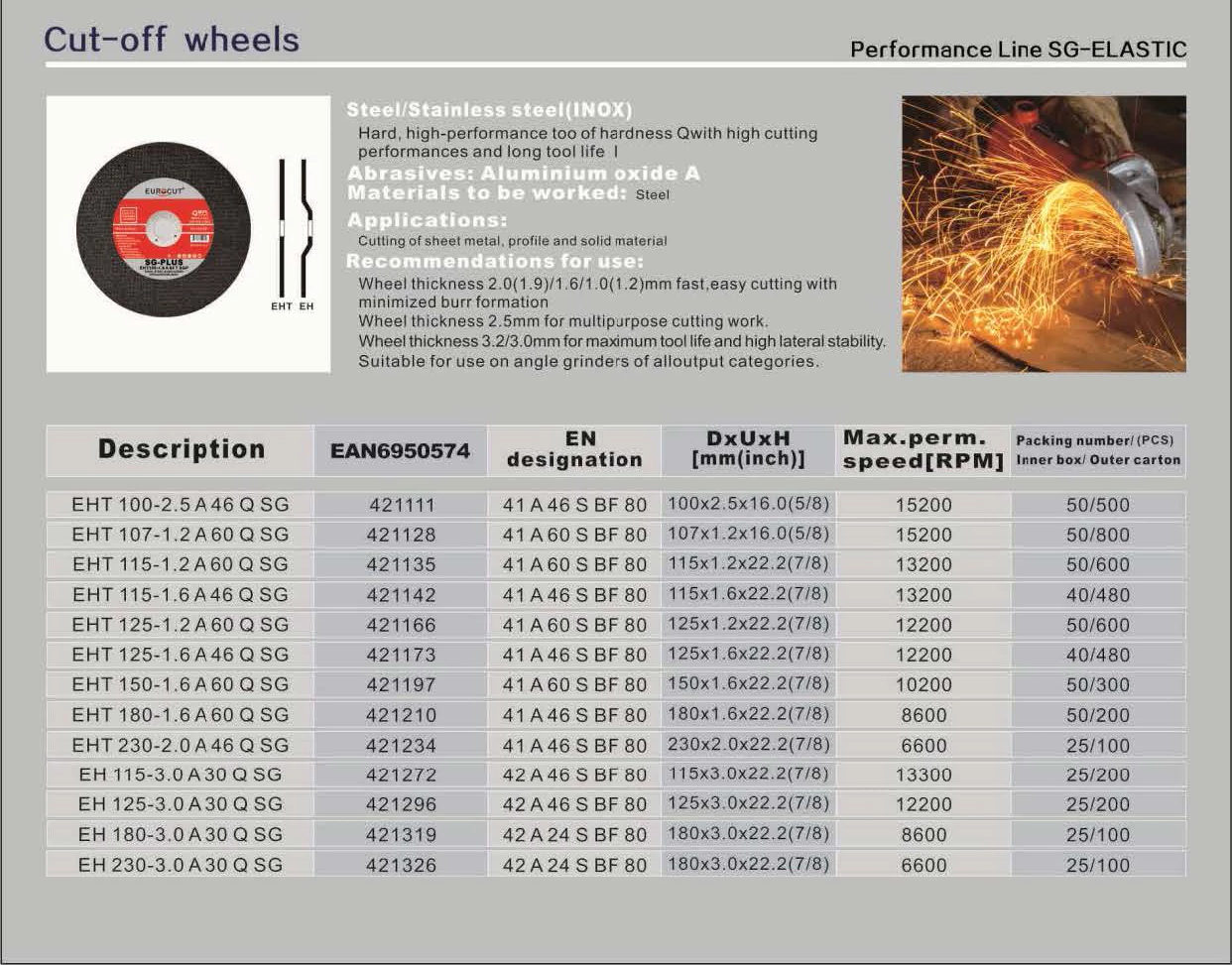

Performance Line SG-ELASTIC

Applicable materials: Steel / Stainless steel (INOX)

Abrasive type: Aluminium Oxide A

Features:

-

Hardness I grade, taking into account both cutting force and wear resistance

-

Low burr cutting, high stability

-

More versatile, suitable for various industrial needs

- Maximum speed 15,200 RPM (depending on the specification)

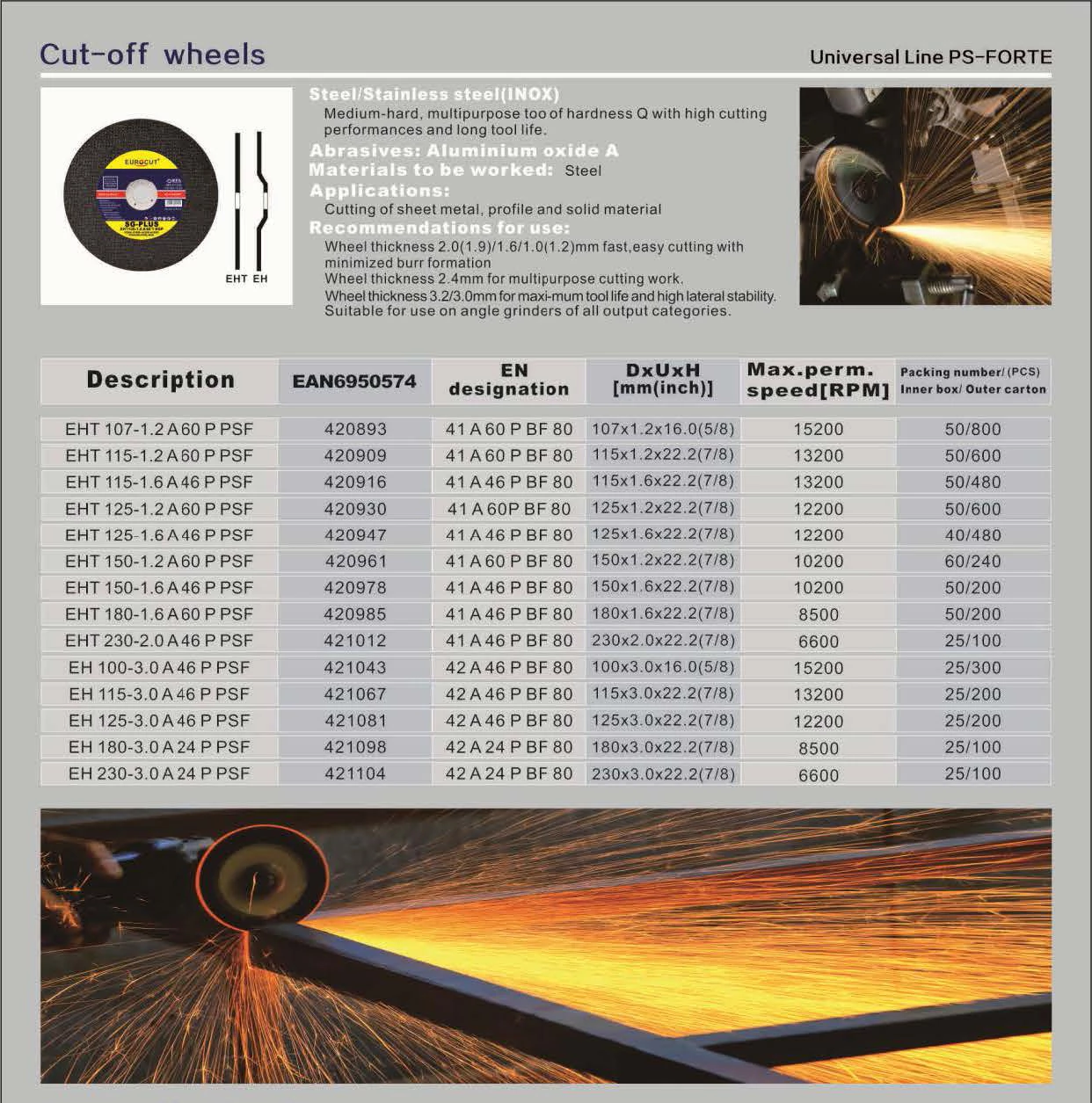

Universal Line PS-FORTE

Applicable materials: Steel / Stainless steel (INOX) Abrasive type: Aluminium Oxide A Features:

- Medium hardness Q grade, balanced performance

- Excellent multi-purpose performance and long life

- Available in thicknesses from 1.6mm to 3.0mm

- Suitable for angle grinders of various output powers

Special Line SG-PLUS

Our grinding wheels and abrasive cutting wheels are suitable for angle grinder discs, providing efficient cutting.

Applicable materials: Stone / Cast iron Abrasive type: Silicon Carbide C Features:

- Extremely high hardness R(C) for high-intensity cutting operations

- Excellent lateral stability and extra-long life

- Suitable for cutting natural stone, artificial stone, refractory bricks, cast iron and non-ferrous metals

- Maximum speed: 15,200 RPM (depending on the specification)

Why Choose Us

-

Improvements on proven and reliable products, maximizing your tool efficiency.

-

Precision grinding, ensuring a scratch-free surface on your workpiece.

-

Significantly extended tool life, tested in real-world applications.

Why Trust Qing Yang

Qing Yang is our carefully developed brand line, aiming to bring you a diverse range of high-performance, high-quality, cost-effective products. Each Qing Yang abrasive tool undergoes rigorous testing of components and production processes, meeting industry standards, and is trusted by engineers worldwide. Only when we are 100% confident in its superior quality will we label it with the Qing Yang brand—this is your guarantee of quality assurance.

Not sure which cut-off wheel fits your job?

Product specifications tell you what a wheel can do. These guides help you decide which one you actually need.

How to Choose the Right Cut-off Wheel for Steel

Material type, thickness, and machine power — the full selection framework explained.

Cut-off Wheel Thickness Explained

When to use 1.0 mm, 1.6 mm, 2.5 mm, or 3.0 mm — matched to real cutting conditions.

Thin Cut-off Wheels: Benefits and Limitations

Where thin wheels improve speed and where they introduce structural risk.

Cut-off Wheels vs Grinding Wheels

Load direction, structural design, and why they cannot substitute for each other.

Common Cut-off Wheel Safety Mistakes

The errors that cause most wheel failures in fabrication environments.

Sizes of Cutting Discs

| MM | INCH | SPEEDR.P.M | SPEEDM/S | PCS/CTN |

| 100X3.0X16 | 4×1/8×5/8″ | 15200 | 80 | 400 |

| 115X3.0X22.2 | 4.5×1/8×5/8″ | 13300 | 80 | 300 |

| 125X3.0X22.2 | 5×1/8X7/8″ | 12200 | 80 | 300 |

| 150X3.0X22.2 | 6×1/8×7/8″ | 10200 | 80 | 200 |

| 180X3.0X22.2 | 7×1/8×7/8″ | 8500 | 80 | 200 |

| 230X3.0X22.2 | 9×1/8×7/8″ | 6640 | 80 | 100 |

Customization Services for Cutting Discs Wholesale

As a professional cutting disc manufacturer, Qing Yang® provides in-depth cutting disc customization services (OEM/ODM) to meet the personalized needs of global industrial customers. We support multi-dimensional technical customization, including:

-

Dimensional specification adaptation: We can produce a full range of sizes from 3-inch cutting wheel to 14-inch cutting wheel, accurately control thickness parameters (such as the critical 2.5mm ultra-thin design to optimize cutting efficiency), and customize the aperture according to equipment requirements (such as 25.4mm standard or special specifications).

-

Material and process upgrade: Optimize the bonded abrasive formula for metal cutting discs or stone cutting discs application scenarios, including options for ceramic cutting discs and granite cutting discs wholesale; support surface modification processes such as high temperature resistant coating and anti-static treatment to match the same level performance requirements of Norton and Klingspor.

-

Brand exclusive design: Based on the needs of cutting disc brand construction, we provide full-process packaging solutions (including customized printing, color identification system) and proprietary technical documents to help customers develop regional markets.

Our customized services cover all categories of products, including angle grinder cutting discs, heavy-duty cutting discs (300mm metal cutting discs), etc. Our technical team can replicate parameters or enhance performance based on the samples provided by customers, and also support small batch proofing and verification.

When cut-off wheels should not be used

Understanding where cut-off wheels work is only half the picture. These guides define the boundaries that prevent tool failure and unsafe conditions.

Why Become a Cutting Disc Distributor

If you’re in the tool wholesale business, you know that cutting tools are among the most practical tools. They’re used in a wide range of industries, from woodworking shops to metalworking shops to stonework. To ensure their efficient operation, they rely on the right accessories! Cutting discs are one of the most common accessories. Unlike tools, they’re consumables, so they’re in high demand. If you’re a wholesaler looking for a quick and profitable product, buying cutting discs in bulk will ensure your success.

Cutting discs are made from a variety of materials, depending on the intended cutting application. Examples include diamond for hard stone, aluminum or silicon for specialized grinding, and steel for everyday strength. As a functional accessory for most grinders and many power saws, investing in wholesale cutting discs opens up a wider customer base, including suppliers and end users of angle grinders, chop saws, circular saws, and other equipment.

Now, let’s talk about the numbers that matter most to your profits.

With a MOQ of just 10,000 pieces (negotiable, of course), combined with Qingyang factory direct pricing, your resale gross margin can easily reach over 30%.

Real-world example: A Middle Eastern importer purchased a large quantity of our 4.5-inch optical discs. Thanks to the stable supply and fast turnover, their annual profits skyrocketed by 25%. This wasn’t a miracle, but rather shrewd purchasing! Now, they’re our most loyal customer and refer us many new businesses.

Here are the benefits distributors like you can enjoy:

- Lightning-fast shipping—shipping within 3 days keeps your shelves full and your customers happy.

- Branding support—Create a unique brand image with your own logo printed on the packaging at no additional cost.

- Flexible customization options—From size to material, you can tailor your products to meet market demands and stand out.

- Rock-solid quality assurance—ISO and MPA certified—sell with confidence, and we’ll take care of the rest.

Our wholesale cutting discs are ideal for distributors seeking high margins. Becoming a Qingyang distributor is more than just selling products; it’s about building a solid profit advantage in the tool industry. Are you ready to share in these lucrative profits?

Cutting Disc Wholesaler Guide: How to Choose a Reliable Abrasive Tool Supplier?

Choosing a cutting disc supplier should be as comprehensive as possible. First, consider the product range.

There are numerous cutting blade types available, each suited to different applications and tools. Key types include:

- Cutting wheels

- Grinding wheels

- Granite cutting discs

- Ceramic cutting discs

Different cutting discs are suited for different equipment. For example, metal cutting discs are best suited for use with angle grinders, chop saws, circular saws, and other power tools used for metalworking. Of course, there are also multi-purpose cutting discs that are versatile and can handle cutting wood, stone, or metal effectively.

A comprehensive inventory is essential for bulk cutting discs, but quality is paramount. Prioritize ISO/MPA certifications and years of industry experience, such as Qingyang’s customized services, which optimize durability for materials like diamond, aluminum, or silicon.

What happy customers have to say

- CEO

Frequently Asked Questions (FAQs)

Q1: What materials do your cutting discs support?

A: These include, but are not limited to, steel, stainless steel, stone, cast iron, and non-ferrous metals. In addition to general applications, we also offer specialized applications such as:

- Grinding wheels for surface finishing

- Abrasive cutting wheels for precise sectioning

- Diamond cup wheels for heavy-duty grinding tasks

Q2: What is the production lead time?

A:

- Standard sizes are in stock and can be shipped within 3 days .

- For non-standard or customized products, the production lead time is approximately 30–40 days .

Q3: Are you a factory or a trading company?

A: We are a professional manufacturer of abrasive tools with over 35 years of experience.

Q4: Do you accept OEM branding?

A: Yes, OEM branding is available . We can also provide free label design services.

Q5: Are samples available for quality testing?

A: Yes, free samples are available for quality testing. However, the shipping cost is borne by the customer.

Q6: Do you have any certifications?

A: Yes, we are certified with MPA and ISO standards.

Q7: How long is the delivery time?

A: Normally, delivery takes about 20 days after receiving payment .

Cut-off Wheel Application Guides

In-depth guides covering selection, thickness decisions, safety boundaries, and tool comparisons — all specific to cut-off wheel applications.

Selection & Application

Choose the right wheel for your material and conditionsHow to Choose the Right Cut-off Wheel for Steel

Material type, thickness, and machine power — the full selection framework.

→ ThicknessCut-off Wheel Thickness Explained

When to use 1.0 mm through 3.0 mm matched to real cutting conditions.

→ Thin WheelsThin Cut-off Wheels: Benefits and Limitations

Speed advantages and structural conditions where thin wheels fail.

→Safety Boundaries

When cut-off wheels should not be usedCommon Cut-off Wheel Safety Mistakes

The operating errors behind most wheel failures in production environments.

→ BoundaryWhen Not to Use Cut-off Wheels

Five scenarios where structural failure risk becomes critical.

→ ComparisonCut-off Wheels vs Grinding Wheels

Load direction, structural design, and why substitution is unsafe.

→