Full Customization

Innovative Solutions

Precision Manufacturing

After Sales Guarantee

Famous Abrasive Tools Manufacturer in China

Qing Yang operates its own state-of-the-art manufacturing facility, equipped with advanced Industry 4.0 automation to ensure precision, efficiency, and consistency in production.

Product Category

We offer cut-off wheels, grinding wheels, flap discs, diamond blades, wire brushes, sanding discs in various sizes. From small die grinding discs to large cut-off saw blades, we have it all. Sizes include 3 inch, 4 inch, 4.5 inch, 5 inch, 6 inch, 7 inch, 9 inch, 12 inch, 14 inch, and 16 inch.

Cut-off Wheels

Precision-engineered aluminum oxide & silicon carbide cut-off wheels for high-speed metalworking. ISO 603 compliance with 0.1mm thickness tolerance. Ideal for steel mills and automotive OEMs.

Learn More

Grinding Wheels

Vitrified-bond grinding wheels for angle grinders. 35m/s max speed, 20% longer lifespan than ANSI standards. Perfect for weld seam smoothing and foundry applications.

Learn More

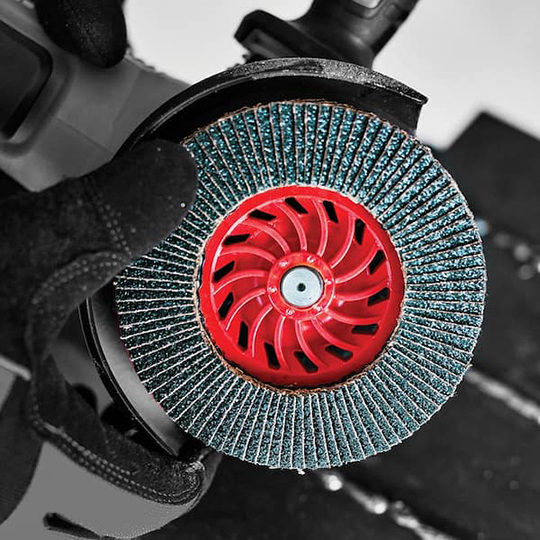

Flap Discs

Zirconia-alumina flap discs with 40+ grit options. 25% faster material removal on stainless steel, carbon fiber, and alloys. OSHA-compliant low-vibration design.

Learn More

Power Tools

Durable, high-torque electric power tools built for industrial use. Ergonomic design with heat-resistant motors ensures 30% longer runtime. Ideal for metal fabrication, automotive repair, and surface finishing applications. CE-certified for safety and reliability.

Learn MoreHot Selling Tools

High-performance tools for metal and construction professionals, with private label Qing Yang series and OEM customization:

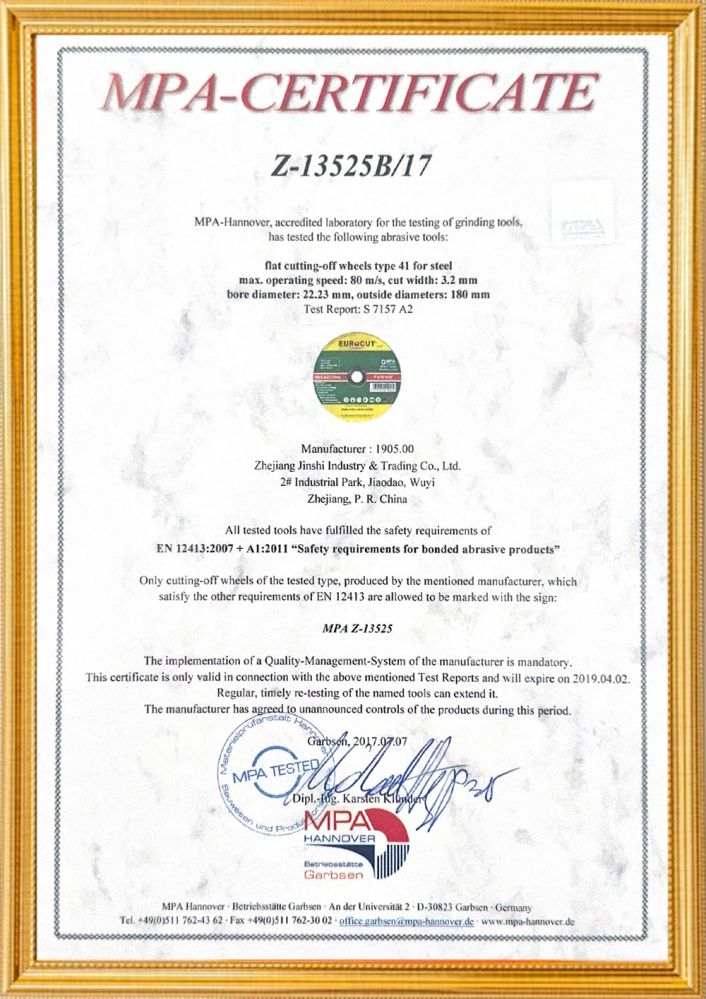

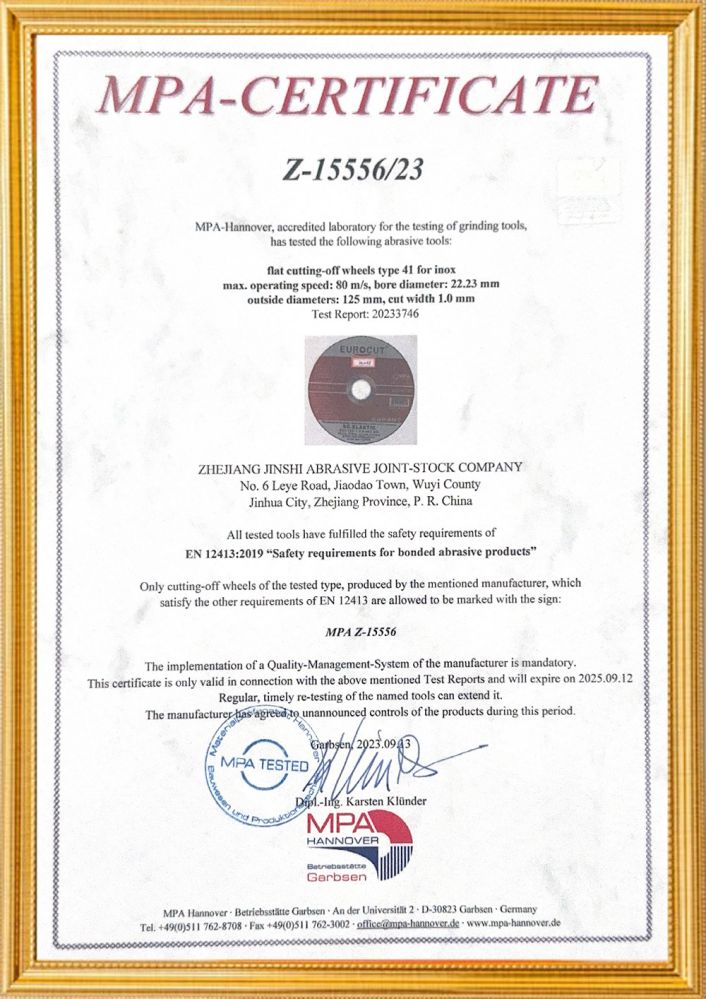

Quality certifications

Discount Alert

Cut-off Wheel

Grinding Wheels

Flaps Discs

Power Tools

Custom Abrasive Tools Manufacturing

OEM/ODM Solutions for Cut-Off Wheels, Grinding Discs & Flap Wheels, ISO-Certified Customization for Industrial Applications.

Custom Abrasive Tools for Metal & Construction

- Custom Cut-Off Wheels: Thin kerf (0.6-1.2mm) | Fiberglass-reinforced

- Heavy-Duty Grinding Wheels: 24-120 grit | Ceramic/Zirconia blends

- Industrial Flap Discs: Non-woven abrasives | Dust-free technology

- Specialty Tools: Non-sparking | High-RPM (15,000+) certified

Industry-Specific Solutions

Low MOQ & High Standard

- Low MOQ Customization: 500pcs trial orders accepted

- Multi-Material Expertise: Aluminum oxide/SiC/Diamond abrasives

- Global Compliance: REACH, RoHS, OSHA, ANSI B7.1 standards

- Fast Turnkey Production: 72hr prototype + 15-day bulk delivery

Technical Capabilities

- Bond Customization: Resin/Vitrified/Hybrid formulations

- Precision Engineering: ±0.1mm dimensional tolerance

- Smart Packaging: Barcode tracking + Custom branding

Certificates

Our abrasive tools factory meets stringent global safety standards.

What happy customers have to say

- CEO

Murthy

Purchase Director

Asif

Business Development Manager

Get In Touch

Contact Our Abrasive Engineers:

✉️ 24h Technical Response

🌍 Global OEM Support

📐 Free Customization Consult