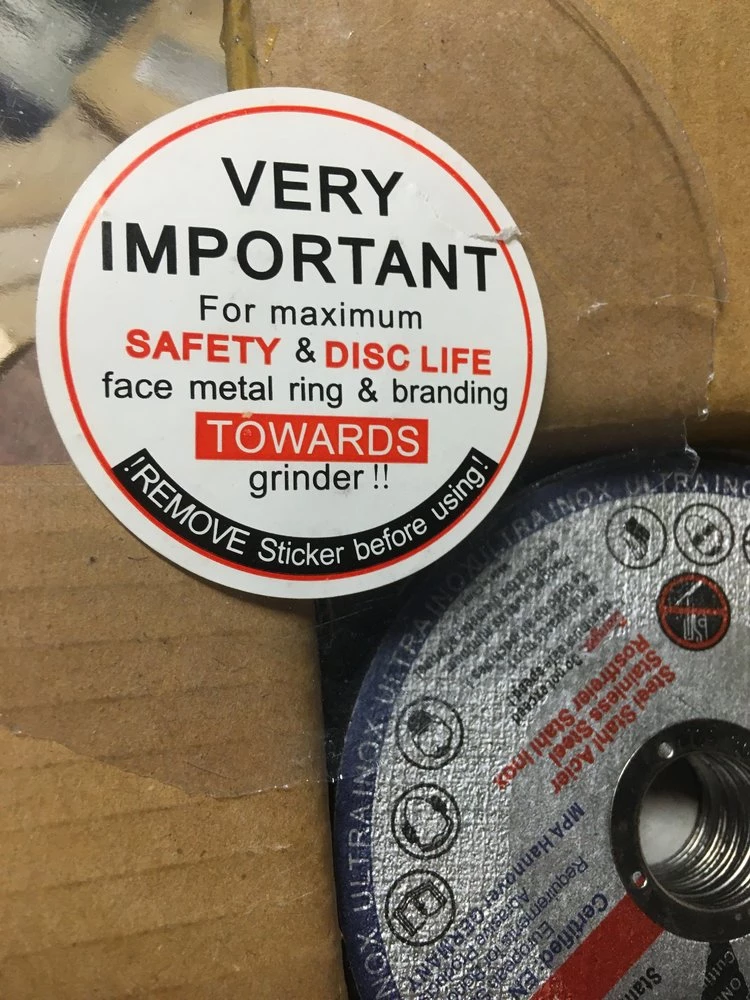

The cutting disc installs with the label side facing outward and the metal ring or hub side facing inward toward the grinder. This setup aligns with the disc’s design for stability and safety, and always match any directional arrow on the disc to the grinder’s rotation—typically clockwise when viewed from the handle.

I know that getting this right prevents disc failure and injuries in a busy workshop. In this article, you’ll learn proven methods for installation, safety, and more.

Understanding Cutting Disc Types

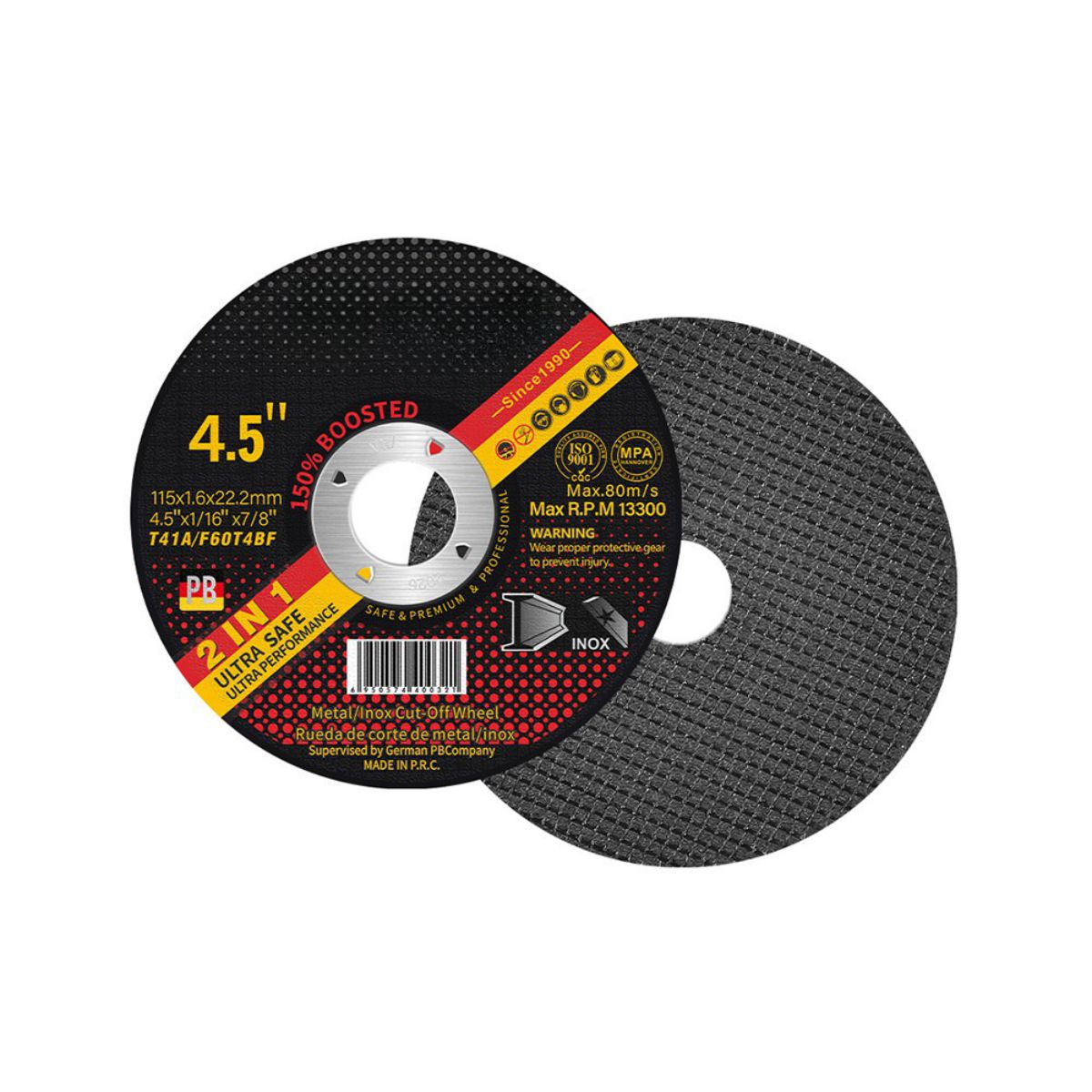

Cutting discs vary by material and purpose, affecting how they mount. Metal cutting discs are thin, abrasive wheels for steel or aluminum, often with a fiberglass reinforcement. Install them label out, hub in, for clean cuts without binding.

Diamond blades suit concrete or tile, with segmented edges for cooling. These usually have clear arrows; align them with the grinder spin to avoid chipping. Flap discs, while more for sanding, mount similarly but prioritize the abrasive flaps facing the work.

Grinding discs are thicker and depressed-center style, where the nut fits into the recess. Knowing your disc type ensures correct orientation from the start. Mismatched types lead to poor performance, as seen in user reports on welding forums.

Why Orientation Matters for Safety and Performance

Proper disc direction reduces risks like shattering, which can send fragments flying at high speeds. Backward installation causes uneven wear, overheating, and kickback, where the tool jerks dangerously.

It also boosts efficiency: the abrasive side contacts the material optimally, speeding cuts and extending disc life. Experts note that reversed discs cut slower and rougher, wasting time on jobs. Safety standards from abrasive manufacturers stress this to prevent accidents in professional settings. What I appreciate is how a simple check saves hassle down the line.

Tools You Need for Proper Installation

Gather essentials before starting. A spanner wrench or the grinder’s included tool locks the spindle for nut removal. Gloves protect hands from sharp edges, and safety glasses shield eyes from debris.

For stubborn nuts, a cross-head screwdriver or adjustable wrench helps. Some grinders need adapters for disc sizes, like 4.5-inch cutting wheel. Keep a clean cloth handy to wipe the spindle. These basics make the process quick and secure, avoiding improvised fixes that damage parts.

Need to purchase high-quality cutting discs in bulk?

Step-by-Step Guide to Installing a Cutting Disc

Follow these steps for a flawless mount.

- First, unplug the grinder or remove the battery. Depress the spindle lock and loosen the outer nut counterclockwise—most threads are left-handed to self-tighten during use.

- Inspect the new disc for cracks or warps. Place it on the spindle with the label facing out, hub against the inner flange. Reattach the outer flange or nut, tightening clockwise just enough to secure without cracking the disc.

- Test spin the grinder unloaded for 30 seconds to check for wobbles. If smooth, you’re ready. This method works for most angle grinders, as confirmed by abrasive specialists.

Safety Precautions Before and During Use

Safety starts with inspection: ensure the disc’s RPM rating exceeds the grinder’s max speed. Wear full PPE—goggles, gloves, ear protection, and a dust mask for fine particles.

Position yourself so the disc spins away from your body, reducing fragment risk. Use the guard always; it deflects debris. Start cuts at a 15-30 degree angle to prevent binding. Ignoring these things can lead to hospital visits, so they should be considered as a priority each time.

Common Mistakes and How to Avoid Them

One frequent error is mounting backward, ignoring labels or arrows, which causes kickback. Avoid by double-checking markings before tightening.

Over-tightening the nut stresses the disc, risking cracks—use hand pressure plus a quarter turn. Using damaged discs invites failure; replace at first sign of wear. Neglecting the guard is another big no, as it exposes you to hazards. Simple habits like reading the manual prevent these pitfalls.

Troubleshooting Common Installation Issues

If the disc wobbles, recheck the nut tightness and flange alignment—debris on the spindle often causes it. Overheating during cuts signals a backward disc or wrong material match; flip it or switch types.

Poor cutting performance? Verify arrow direction matches the grinder’s spin. If the nut won’t loosen, apply penetrating oil and retry. These fixes keep your setup reliable, based on real user troubleshooting in tool communities.

Best Practices for Longevity and Performance

To maximize disc life, cut in straight lines with light pressure—let the tool do the work. Cool the disc between long sessions to prevent glazing.

Store discs flat in a dry area to avoid warping. Rotate stock to use older ones first. Match disc grit to the job: coarse for rough cuts, fine for precision. These practices extend usability and cut costs, as experienced users recommend.

Maintenance Tips for Your Grinder and Discs

Regular maintenance keeps everything running smoothly. Clean the grinder’s vents and spindle after use to remove buildup. Lubricate moving parts per the manual.

Inspect discs before storage for edge wear—replace if diameter shrinks below 50% original. Sharpen or dress grinding discs as needed. Annual checks on cords or batteries prevent failures. This routine builds trustworthiness in your tools.

I know that mastering disc installation transforms your grinding tasks from frustrating to efficient. Always consult your grinder’s manual for model-specific details.

FAQs

Can you use a smaller disc on a grinder?

Yes, if it fits the arbor and the guard adjusts properly. Smaller discs work for tight spaces but ensure the RPM rating matches to avoid overload. This is common for detail work, as noted in plumbing guides.

What if there’s no arrow on the disc?

Fall back on the label side out rule, with the reinforced hub facing the grinder. Test for smooth spin; if it binds, flip it. Budget discs often lack arrows, but this method holds up in practice.

How often should I replace a cutting disc?

Replace when worn to half size, cracked, or after heavy use showing glazing. Visual checks before each job catch issues early, preventing mid-cut failures. Experts suggest every 10-20 hours of runtime, depending on material.

What’s the difference between cutting and grinding discs?

Cutting discs are thin for slicing through materials, while grinding discs are thicker for surface removal and shaping. Mount grinding ones with the depressed center down; confusing them risks inefficiency or breakage.

Can a cutting disc be used for wood?

Yes, but choose carbide-tipped or specialized wood discs to avoid burning or kickback. Standard metal ones gum up with resin. Align the gear direction of the sharpener with the direction of rotation of the sharpener to ensure safe and clean cutting.

Is it safe to cut without the guard?

No, never remove the guard—it protects against disc explosions. Regulations and safety pros insist on it, even for quick jobs. Guards deflect shards, saving eyes and limbs in worst-case scenarios.