Performance Advantages of Our Electric Eccentric Sander

- Multi-scenario adaptation: compatible with surface treatment requirements of materials such as wood, metal, marble, etc., covering scenes from automotive polishing to industrial-grade precision grinding.

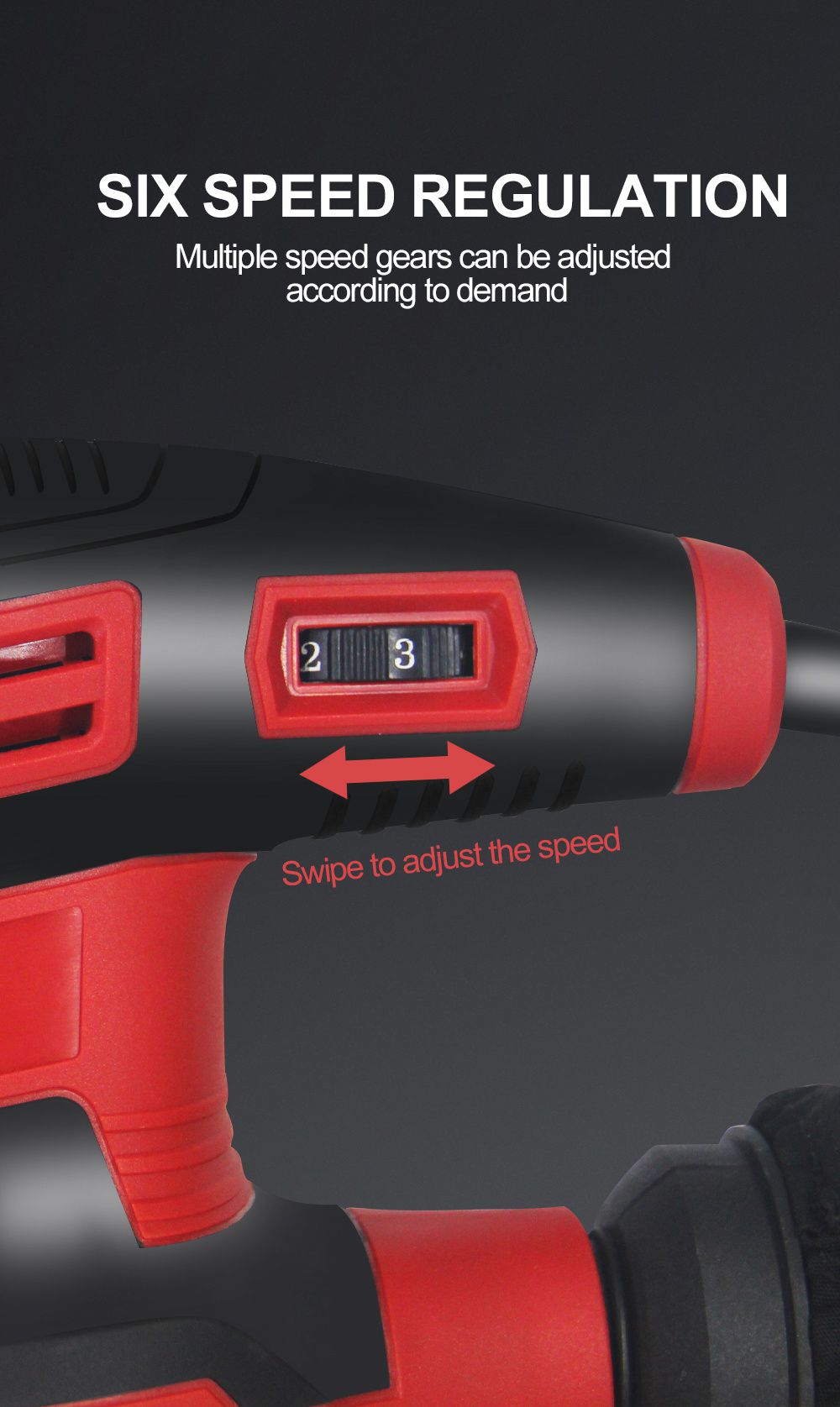

- Intelligent power control: 6-speed speed adjustment system (6000-13000rpm) accurately matches the processing strength of materials with different hardness to ensure a balance between operating efficiency and surface treatment quality.

- Engineering-level dust removal design: integrated vacuum adsorption bottom plate and dustproof switch structure, reducing 80% of operating dust, in line with EU CE standard working environment specifications.

All copper motor

Strong power

Shock absorption design

Rapid heat dissipation

Equipment Application Range

This series of electric eccentric sanders are suitable for scenes such as automobile repair centers, building materials processing plants, and metal casting workshops. The specific functions include:

- Automobile finishing: paint polishing, weld grinding

- Building materials pretreatment: artificial quartz countertop chamfering, granite burr correction (refer to Diamond Productions International Construction Guide)

- Metal processing: casting burr cleaning, stainless steel pipe surface brushing (compatible with Norton Abrasives sanding disc specifications)

Product Parameters

| Technical parameters | Specifications |

|---|---|

| Rated Voltage | 230V ±10% AC |

| Idle Speed | 6000-13000 rpm (6-speed precision adjustment) |

| Vibration amplitude | 2mm (eccentricity, in accordance with DIN EN 60745 vibration control standard) |

| Grinding Plate System | 125mm diameter 360° rotating polishing disc (compatible with Bosch/Makita sandpaper specifications) |

| Rated power | 350W industrial-grade copper wire motor (continuous load duty cycle: 30 minutes/hour) |

| Disc Compatibility | Standard 5-inch (127mm) self-adhesive/self-adhesive sandpaper |

| Gear position | 6-level electronic speed regulation (with automatic load compensation function) |

| Wire length | 1.8m reinforced rubber cable (H05RN-F 3G1.5mm² wire gauge, VDE certified) |

System Components

Standard configuration includes 125mm self-adhesive sanding disc (compatible with 3M™ Cubitron™ II abrasive), detachable dust bag and anti-vibration handle. Supported options:

| Component type | Technical parameters | Certification standards |

|---|---|---|

| Carbon fiber sanding disc | Ø125mm/6-hole positioning system | ISO 603-2016 |

| Industrial dust collection module | 2.5L capacity/cyclone separation structure | EN 60335-2-69 |

| Anti-static grinding base | Conductive rubber material/360° rotation structure | IEC 61340-5-1 |

Engineering customization solution

Provide ODM/OEM in-depth cooperation mode, which can be carried out according to customer needs:

- Voltage customization: Support 110V/220V/380V multi-voltage system

- Power upgrade: Up to 550W industrial motor can be configured

- Safety enhancement: Add IP54 protection grade housing

Surface finishing capability

Using German FEPA standard P80-P3000 mesh abrasives, it can achieve:

- Roughing: single cutting depth 0.2mm (steel)/0.5mm (wood)

- Fine grinding: surface roughness Ra≤0.8μm (equivalent to Walter Surface Technologies process standard)

- Special treatment: support titanium alloy mirror polishing (need to be matched with diamond grinding block accessories)

Business cooperation terms

- Bulk purchase policy: 15% discount on FOB price for orders of 50 units, LC/TT payment accepted

- Logistics guarantee: 15 working days door-to-door delivery in the Middle East/Southeast Asia, Allianz freight insurance

- After-sales system: 36-month motor warranty, 7×24 hours English/Portuguese technical support

Global application cases

In areas such as the Brazilian automotive parts manufacturing cluster, the Malaysian stone processing park, and the Polish metal casting industrial belt, this equipment operates an average of 12 hours per day, and the key component life test data are:

- Carbon brush life: ≥800 hours

- Bearing durability: 2000 hours without gap

Disclaimer: The brands mentioned in this article, such as 3M, Bosch, and Norton Abrasives, are owned by their trademark owners. There are design differences between the technical parameters of this product and the benchmark model. The actual performance is subject to physical testing.