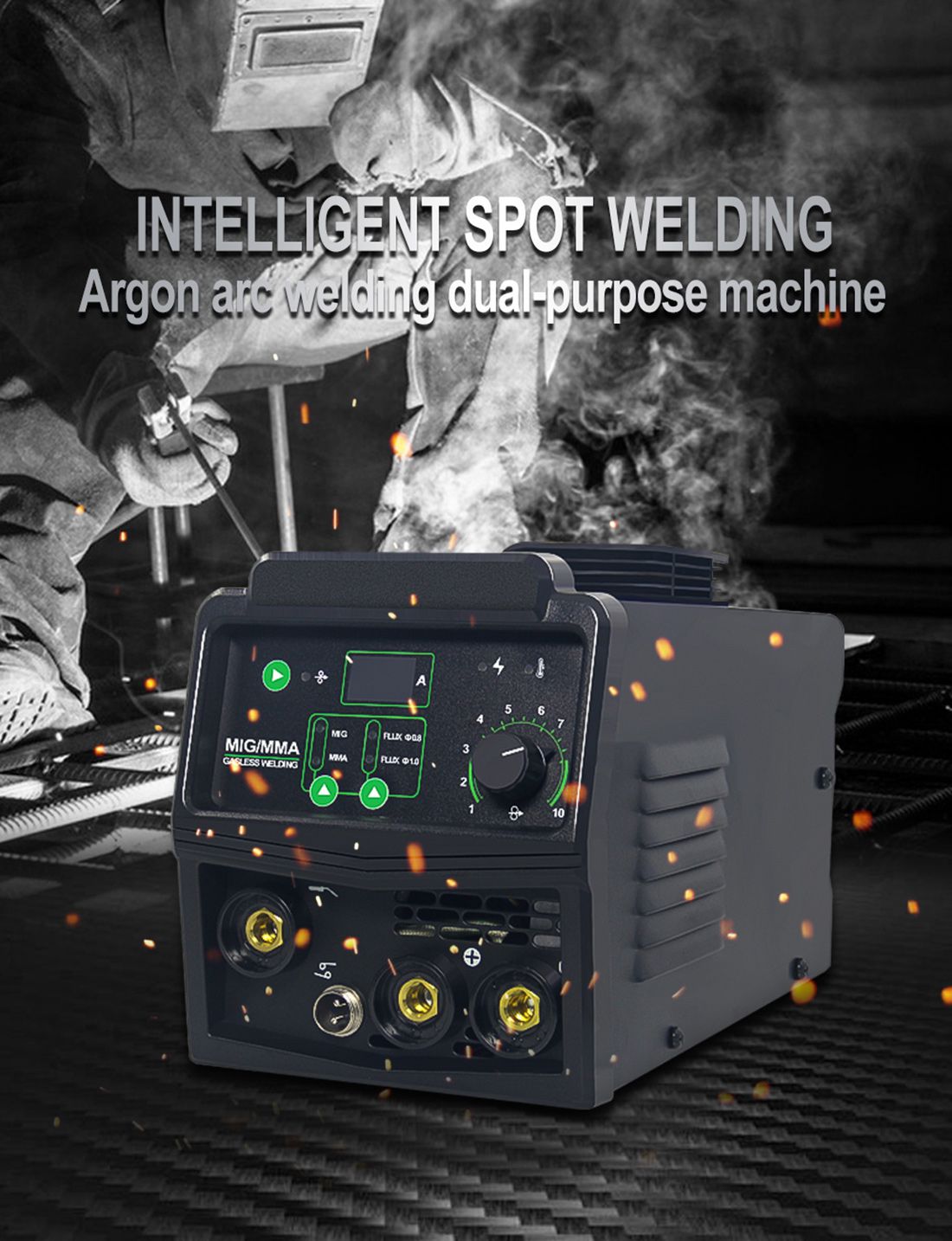

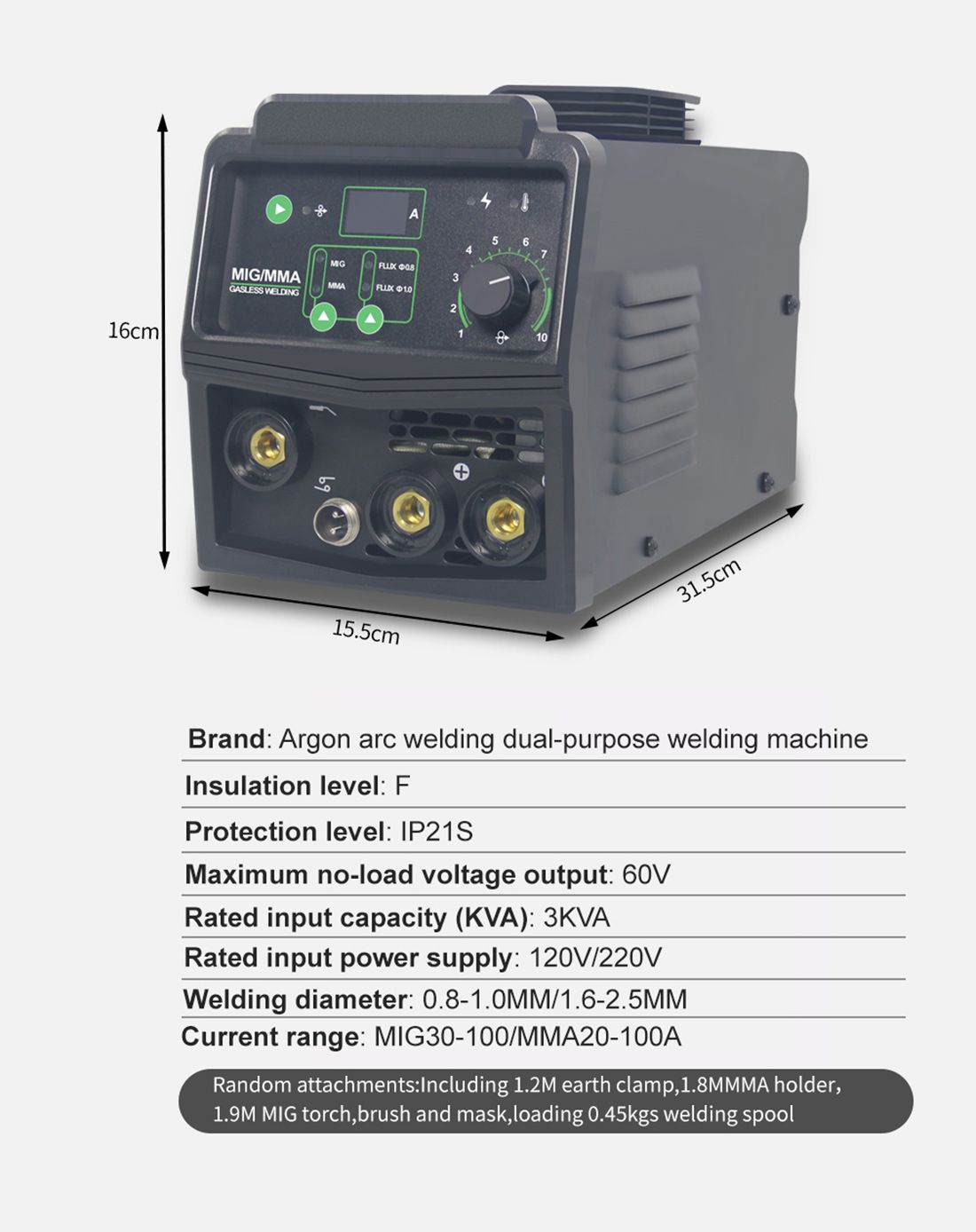

| Parameter | Value |

|---|---|

| Brand | Argon Arc Welding Dual-Purpose Machine |

| Insulation Level | F |

| Protection Level | IP21S |

| Max No-load Voltage Output | 60V |

| Rated Input Capacity | 3 KVA |

| Rated Power Supply | 120V / 220V (Dual Voltage) |

| Supported Welding Diameter | 0.8–1.0mm (MIG), 1.6–2.5mm (MMA) |

| Current Range | MIG: 30–100A / MMA: 20–100A |

Technical features

- IGBT inverter module realizes intelligent spot welding and argon arc welding dual-mode intelligent switching

- 120V/220V dual voltage input adapts to global power grids, 3KVA capacity ensures continuous stable output

- Seven-channel cooling system is IP21S certified and supports 4 hours of continuous MMA welding

Industrial welding solution

This machine integrates spot TIG welder function, which can handle 0.8-2.5mm steel welding and spot welding positioning. It adopts a modular design similar to Lincoln Electric Power MIG 210MP, and the mode switching time is 30% shorter than conventional equipment.

Standard configuration list

- 1.9m MIG welding gun (compatible with 0.8-1.0mm welding wire)

- 1.8m MMA welding handle (compatible with 1.6-2.5mm welding rod)

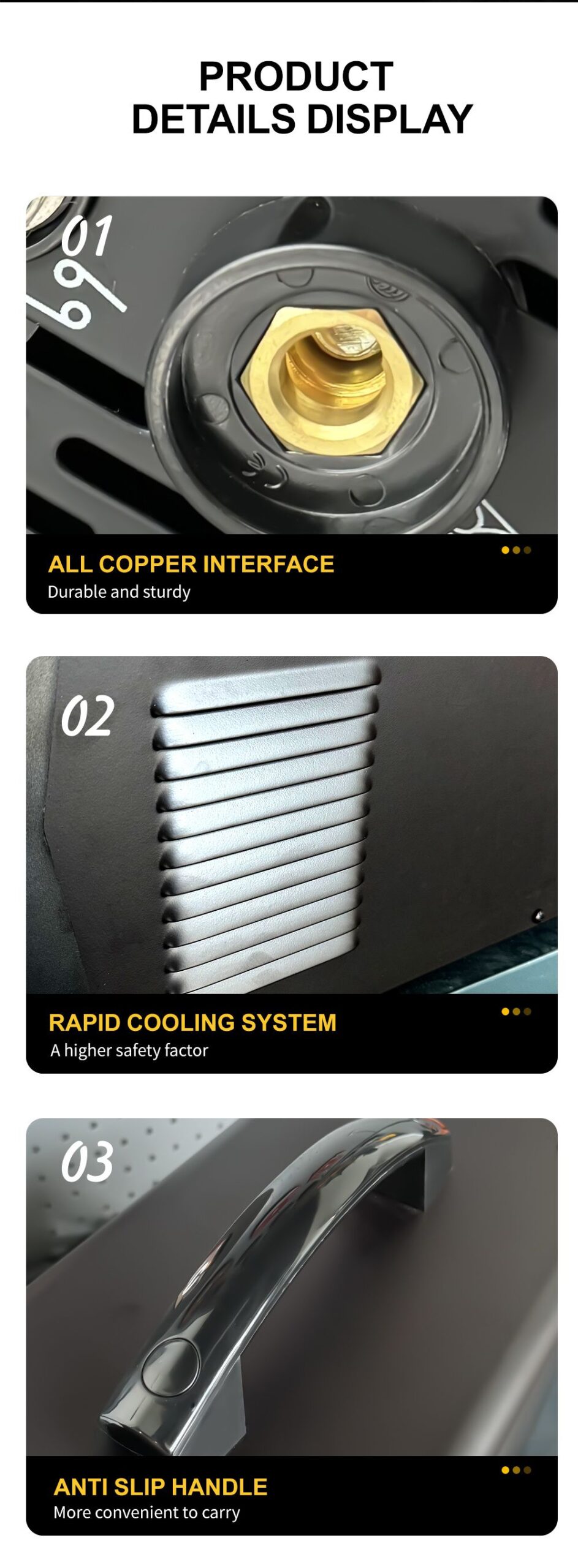

- Intelligent temperature control ground wire clamp (all copper interface)

- Protective mask and cleaning tool set

Customized production plan

| Adjustable parameters | Adjustment range |

|---|---|

| Input voltage | 110V/220V (compliant with UL/CE standards) |

| Welding current | MIG 30-100A / MMA 20-100A |

| Wire diameter | Support ESAB 0.6-1.2mm standard specifications |

Process performance parameters

- No-load voltage fluctuation ±3V (better than EN 60974-1 standard)

- TIG arc welding arc starting success rate ≥99.2% (40℃ environmental test)

- Spot welding positioning accuracy ±0.3mm (1mm galvanized steel plate test)

Global service system

Technical centers are set up in Sao Paulo, Brazil and Warsaw, Poland, providing:

- 72-hour emergency parts supply (covering Thailand/Vietnam/Malaysia)

- Multi-language operation video guidance (including English/Arabic/Portuguese)

- Annual agreement customers enjoy free equipment calibration service

Bulk purchase policy

Basic order: 15 units (support dual-purpose welding machine mixed loading)

Customized order: 50 units (enjoy 10% discount on FOB price)

Agency cooperation: Regional exclusive authorization + market promotion subsidy

Key market verification

The product has passed the TÜV SÜD 600-hour durability test and has been used in:

- Saudi Jeddah Automobile Repair Center (annual consumption of welding wire 12 tons)

- Pune Metal Processing Plant, India (welding qualification rate 98.5%)

- Warsaw Industrial Park, Poland (spot welding efficiency increased by 40%)

Disclaimer: The brand names mentioned in this article, such as Lincoln Electric and ESAB, belong to their owners, and the technical parameters of Qing Yang® equipment are based on the test data of its own laboratory.