Qing Yang Grinding Disc Product Introduction

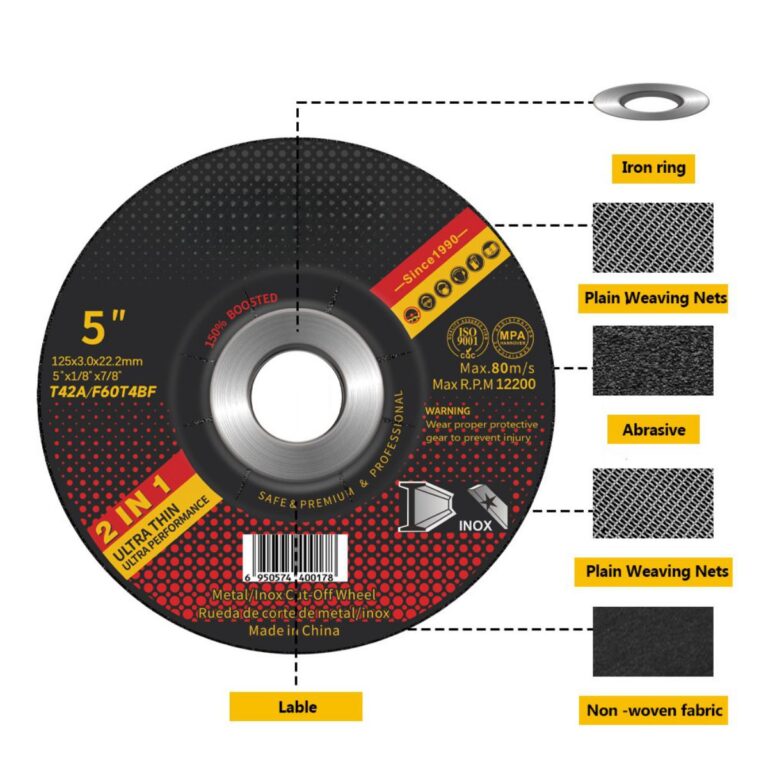

Qing Yang® is a leading manufacturer in China, focusing on grinding wheel products in the B2B market. Our core product 5 inch grinding wheel (125×3.0×22.2mm specification, i.e. 5” x 1/8” x 7/8”) is widely sold globally and is suitable for industrial surface preparation needs. The following content is based on detailed descriptions of actual product characteristics.

Product Advantages

As professional grinding wheel manufacturers , we enhance product performance through advanced processes:

- Enhanced wear-resistant design :Using high-strength abrasive particles, significantly extending product life

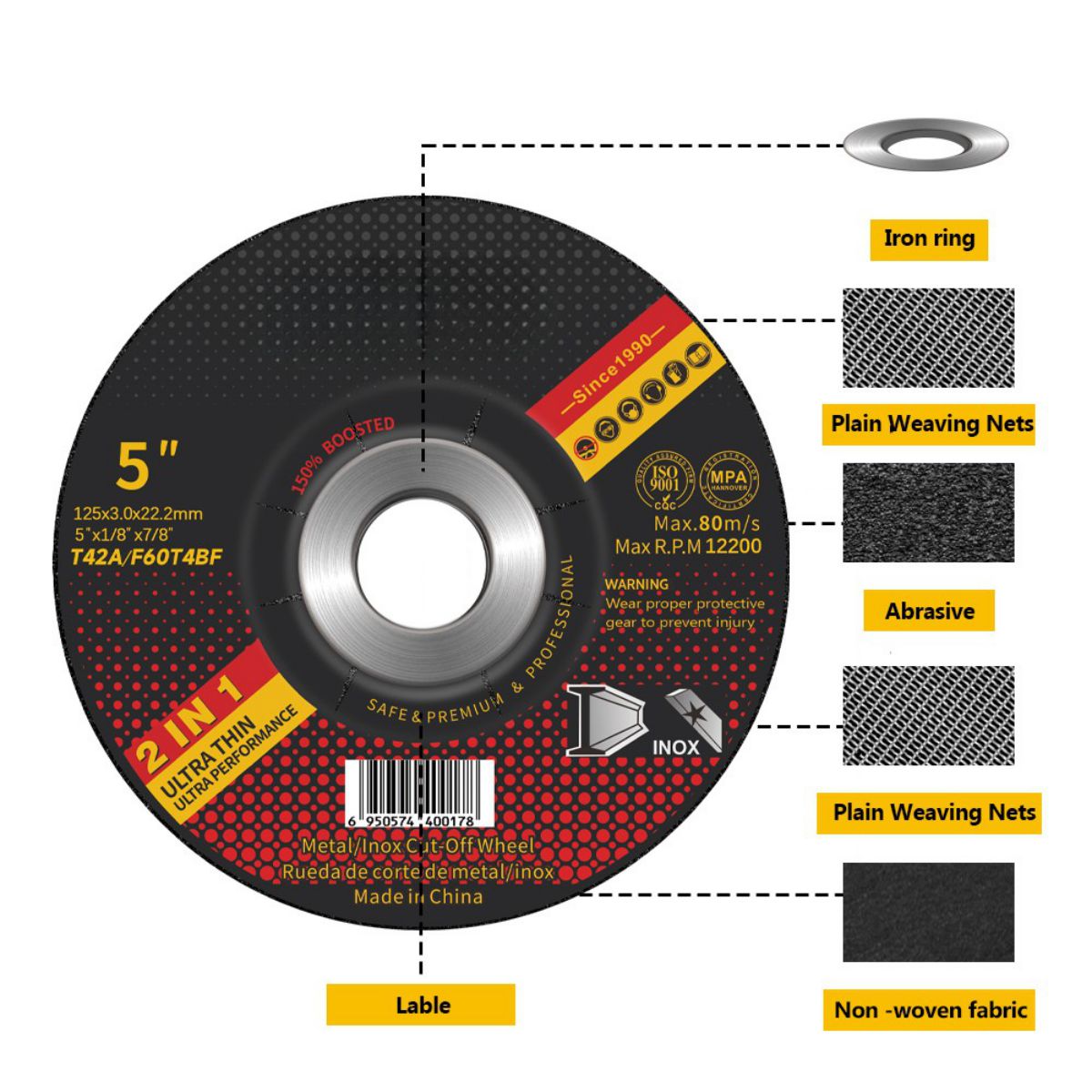

- Efficient grinding performance :Optimized thin thickness (3.0mm) reduces resistance for precise material removal

- High anti-fracture protection :Double-layer glass fiber reinforcement ensures operational safety\ These features support metal finishing and construction applications, complying with industry standards

Main application areas

Qing Yang® grinding wheels are used in industrial material processing:

- Metal processing :Stainless steel and tool steel surface preparation

- Weld grinding :Smoothing welds on pipes and structural components

- Construction engineering :Concrete surface treatment and rebar finishing

- Automotive machinery :Burr removal on metal frames and part refinishing

As grinding wheel suppliers, our products such as 125mm grinder discs are compatible with a variety of equipment types.

Accessories and compatibility

Our 125mm grinding wheels support mainstream equipment:

- Compatibility :Fits 125mm angle grinders (Bosch, Makita, etc.)

- Accessories :T42 fixing nuts included for plug-and-play use

| Parameter | Value | Function Description |

|---|---|---|

| Outer diameter | 125mm | Standard 5 inch grinding wheel |

| Thickness | 3.0mm (1/8″) | Optimized for material removal rate |

| Aperture | 22.2mm (7/8″) | Fits standard 7/8″ arbors |

| Speed rating | 80m/s | 12,200 RPM operational stability |

This specification of grinding wheel 125mm, maintains stability in high temperature environment.

Custom service capabilities

As grinding wheel factories , we provide:

- OEM/ODM support :Custom sizes/logos (e.g. specific 5” grinding wheels)

- Surface treatment :Multiple color options (blue/yellow coatings)

Customizations via ISO-certified processes, no minimum order restrictions

Customer Service Support

As grinding wheel suppliers , we offer:

- Free samples for performance verification

- Technical guidance for grinding efficiency optimization

- 24/7 support for wholesale clients

Wholesale customers can enjoy 24-hour service response to ensure project continuity.

Wholesale policy details

- Volume-based pricing with transparent cost structure

- Global logistics to Saudi Arabia, Singapore, USA, etc.

This policy is directly supplied from the grinding wheel factory to reduce the cost of intermediate links.

Hot-selling target market

As a china grinding wheel supplier, products have been sold to multiple regions:

- Middle East and Africa: including Oman, Kuwait, South Africa and Mozambique markets for construction projects.

- Europe and the United States: such as Poland, Ireland, Italy and other industrial areas.

- Asia: Singapore and Vietnam markets are growing strongly. Markets are expanding, such as 125mm angle grinder discs are widely used in Brazil.

Minimum order requirements

- Standard MOQ:100,000 pieces (mixed specifications accepted)

- Flexible MOQ:Negotiable down to 300 pieces for recurring orders

Disclaimer: The third-party brands mentioned in this article (such as Bosch or Makita) are for industry reference only. Qing Yang® has no commercial cooperation or affiliation with them. It is only intended to illustrate compatibility and application scenarios. All statements are based on public industry information and no infringement is intended.