Grinding Wheel Manufacturer

With factory‐direct wholesale pricing, we excel as a grinding disc manufacturer—your go‑to grinding wheel supplier for quality products and exceptional service.

Grinding wheels are used for material removal, weld grinding, and surface preparation in metal fabrication and industrial maintenance. Compared with cut-off wheels, grinding wheels are designed to withstand continuous side pressure and sustained contact with the workpiece.

This page is intended for industrial buyers, distributors, and fabrication workshops selecting grinding wheels for repeated production use. Common wheel types are presented based on material type, grinding angle, and load intensity, with a focus on stable cutting behavior, heat control, and consistent performance across production batches.

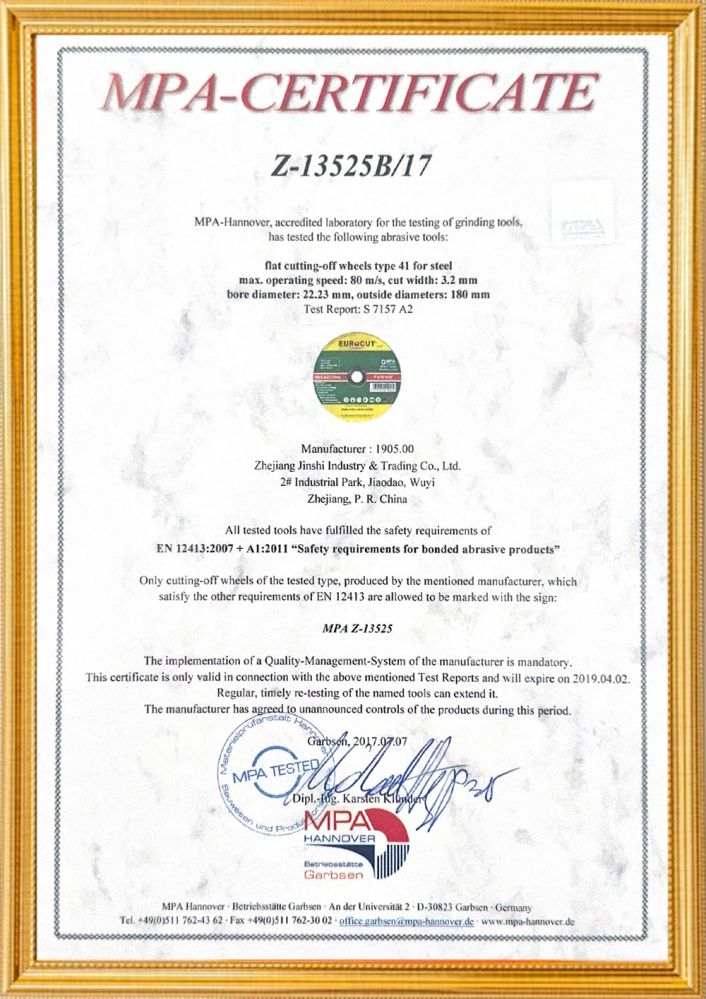

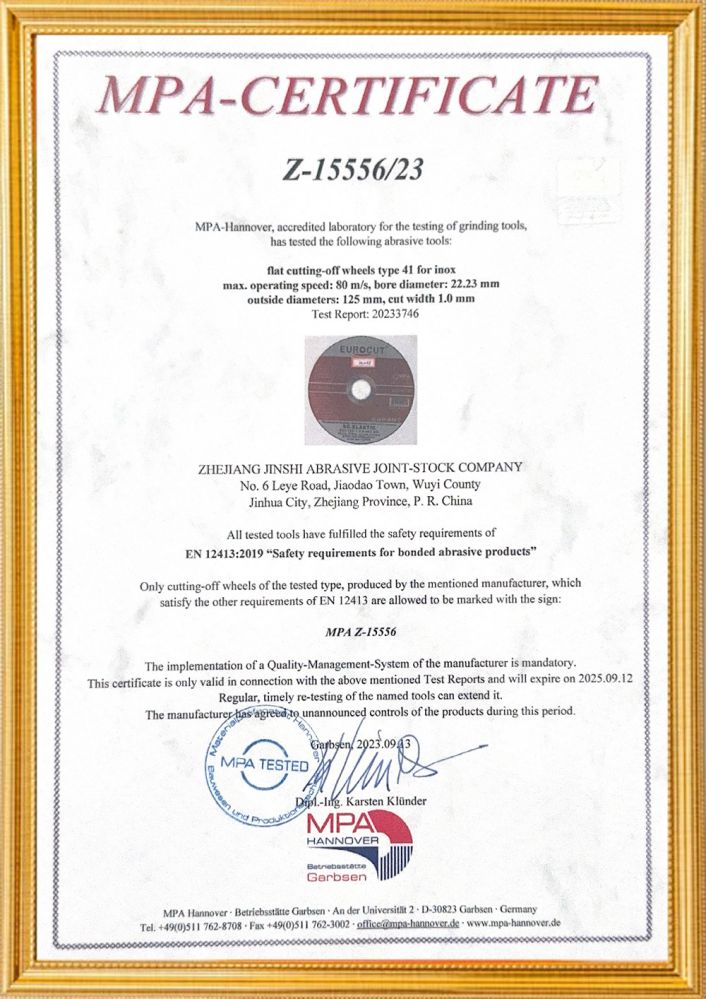

Certificates

We provide a comprehensive selection of grinding wheels designed for efficient material removal across various applications. Each wheel undergoes strict quality inspection and is engineered for compatibility with all standard angle grinders, ensuring reliable performance and long-lasting durability in demanding industrial environments. Our grinding wheels are certified by MPA-Germany, the highest international certification for abrasive products, further demonstrating our commitment to safety, performance, and quality.

What grinding wheels are designed to do

Grinding wheels are bonded abrasive tools used to remove material, shape surfaces, and prepare edges. Unlike cut-off wheels, which are designed for straight cutting, grinding wheels are intended to withstand continuous contact, higher side pressure, and sustained friction.

In metal fabrication and industrial maintenance, grinding wheels are used for weld preparation, surface cleaning, deburring, edge shaping, and defect removal. Their performance directly affects grinding efficiency, surface finish, tool control, and operator safety.

From a manufacturing standpoint, grinding wheels are mechanically more demanding than cut-off wheels. They must maintain structural integrity under side load while delivering controlled material removal. This makes abrasive selection, bond formulation, reinforcement design, and curing control especially critical.

This page explains how grinding wheels are made, how different designs behave in real working conditions, and how to choose the correct grinding wheel based on application and operating environment.

Common types of grinding wheels used in metalworking

Depressed center grinding wheels

Depressed center grinding wheels, commonly known as Type 27, are the most widely used grinding wheels for angle grinders. The recessed hub allows the wheel to be used at a shallow angle, making it suitable for surface grinding and weld removal.

They are typically used for:

-

Weld seam grinding

-

Edge preparation

-

Surface leveling

-

Rust and paint removal

Their design provides a balance between accessibility and stability, especially in fabrication and construction work.

Flat grinding wheels

Flat grinding wheels are used where full surface contact is required. They are more common on stationary grinders or specialized equipment and are selected for controlled, even material removal.

Thin grinding wheels around 6 mm

Grinding wheels with thickness around 6 mm are often used as a crossover between cutting and grinding. They allow light grinding while offering better control than thicker wheels.

In practice, these wheels are chosen when:

-

Space is limited

-

Operators want more precision

-

Excessive material removal is not required

However, their use still requires correct technique to avoid excessive side pressure.

Abrasive materials and grinding behavior

Aluminum oxide and white aluminum oxide

Aluminum oxide is the most commonly used abrasive for grinding carbon steel. It offers stable performance, predictable wear, and good cost efficiency.

White aluminum oxide has higher purity and breaks down more easily during grinding. This self-sharpening behavior reduces heat buildup and makes it suitable for stainless steel and heat-sensitive applications.

In real use, white aluminum oxide grinding wheels often provide smoother grinding action but may wear faster if applied with excessive pressure.

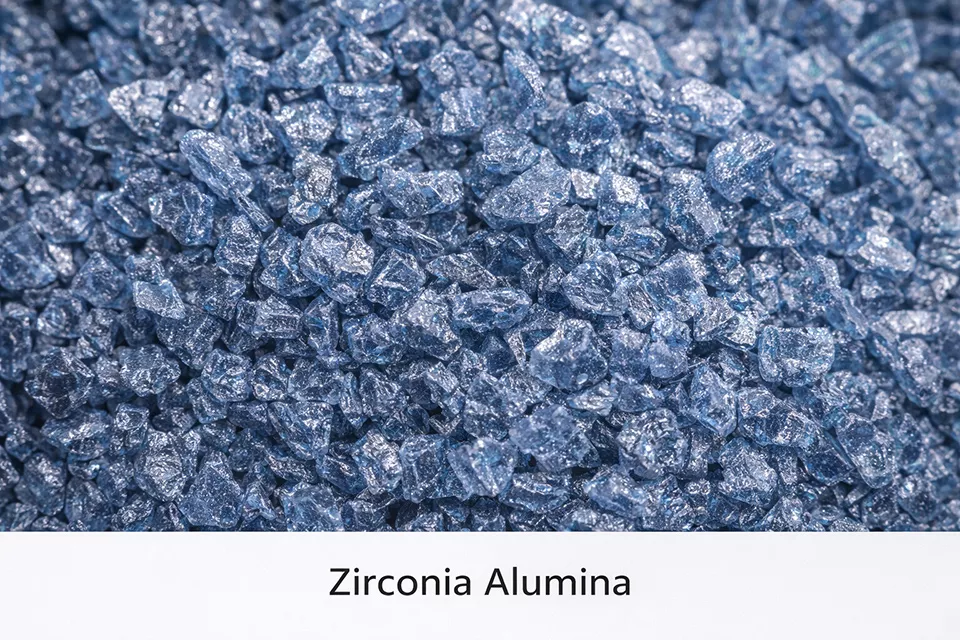

Zirconia alumina abrasives

Zirconia abrasives are tougher and more impact-resistant than standard aluminum oxide. They are often selected for heavy-duty grinding where sustained pressure is applied.

However, zirconia performs best when grinding pressure is sufficient to activate its self-sharpening mechanism. In light grinding or high-speed, low-pressure applications, zirconia may not show its full advantage.

This is a common misunderstanding in the market, where zirconia is sometimes promoted as universally superior regardless of application.

Ceramic abrasives in grinding wheels

Ceramic abrasives offer aggressive cutting and long life in demanding applications. They are used in high-performance grinding wheels designed for industrial production environments.

Their use requires precise bond formulation and controlled manufacturing. Without proper bond balance, ceramic abrasives can feel overly aggressive or unstable in handheld applications.

Bonding systems and wheel hardness

Grinding wheels rely on resin bonding systems that balance hardness and elasticity. The bond must be strong enough to hold abrasive grains under pressure, yet flexible enough to release dull grains and expose new cutting edges.

Wheel hardness is not a simple indicator of strength. A harder wheel does not always last longer. In many grinding applications, a slightly softer bond allows for better self-sharpening and lower heat generation.

In manufacturing, bond formulation is adjusted based on:

-

Abrasive type

-

Wheel thickness

-

Intended application

-

Target market expectations

This balance has a significant impact on grinding feel and service life.

Reinforcement structure and safety considerations

Grinding wheels are reinforced with fiberglass mesh to withstand side pressure and rotational forces. A commonly used structure is multi-layer fiberglass reinforcement, often arranged in a 2+1 sandwich configuration.

This reinforcement improves:

-

Resistance to side loading

-

Structural stability during grinding

-

Safety under high RPM

Inadequate reinforcement is one of the most common causes of grinding wheel failure, especially when wheels are used aggressively or at improper angles.

Manufacturing processes and practical experience

Pressing methods and density control

Grinding wheels can be produced using cold pressing, semi-hot pressing, or hot pressing. Each method affects internal density and bond distribution.

Cold pressing is efficient and widely used, but in thicker grinding wheels, uneven density can lead to inconsistent grinding behavior. Semi-hot or hot pressing is often applied to improve density uniformity and edge strength.

In practice, the choice of pressing method is driven by wheel thickness and expected grinding load, not by production speed alone.

Curing and bond stabilization

After pressing, grinding wheels undergo controlled curing to stabilize the resin bond. Proper curing ensures:

-

Consistent hardness

-

Stable grinding behavior

-

Resistance to thermal degradation

Under-curing results in soft wheels with rapid wear, while over-curing can make wheels brittle and prone to cracking. This balance is achieved through validated process ranges based on resin system and wheel geometry.

Quality control in grinding wheel production

Professional manufacturers implement multiple quality checks, including:

-

Dimensional inspection

-

Visual inspection

-

Speed and burst testing

-

Balance checks for larger wheels

These controls are essential for safety and performance consistency, especially for export markets with varying operating conditions.

How pressing method affects grinding wheel stability

Grinding wheels behave very differently from cut-off wheels in actual use. During grinding, the wheel is under constant side load and continuous contact with the workpiece. This means internal density and bond distribution have a much greater impact on stability than they do in cutting applications.

In our production, we learned early on that using cold pressing alone for certain grinding wheel specifications often leads to problems that only appear during real grinding. Wheels may look normal after curing, but once under load they can start to vibrate, glaze unevenly, or wear faster on the edge. These issues are usually related to density inconsistency that is difficult to detect visually.

For this reason, we do not apply a single pressing method to all grinding wheels. For specific diameters and thicknesses where stability is more critical, we use semi-hot or hot pressing to improve density uniformity. This choice is made to improve grinding control and reduce the risk of unstable behavior during prolonged operation.

Practical trade-offs in grinding wheel production

In grinding wheel manufacturing, higher hardness or faster production does not automatically result in better performance. In fact, pushing either parameter too far often creates new problems in real use.

Very hard grinding wheels may last longer in controlled tests, but in daily operation they tend to generate more heat, lose cutting efficiency, and increase operator effort. Over time, this leads to lower productivity and inconsistent surface results. These effects are especially noticeable in continuous grinding or in high-temperature working environments.

Based on feedback from different applications and export markets, we adjust bond strength and pressing methods to keep a balance between wear rate, cutting feel, and operational stability. Our decisions are not driven by laboratory data alone, but by how the wheel performs under actual pressure, heat, and working habits on site.

Typical grinding applications in real use

Grinding wheels are used in:

-

Structural steel fabrication

-

Welding preparation and finishing

-

Construction and infrastructure work

-

Equipment maintenance

-

Industrial repair operations

In high-temperature regions such as Southeast Asia, South America, and the Middle East, prolonged grinding cycles can increase thermal stress on wheels. In these conditions, bond stability and reinforcement quality often matter more than nominal abrasive grade.

When a grinding wheel is not the right choice

Grinding wheels are designed for material removal under controlled side pressure, but they are not suitable for every operation. In practice, many performance and safety issues come from using a grinding wheel in situations where a different tool would work better.

One common mistake is using a grinding wheel for straight cutting. Even though the wheel may appear strong, grinding wheels are not designed for edge-on cutting forces. This often leads to excessive heat, rapid edge wear, and increased risk of wheel damage. For straight cuts, a cut-off wheel is the correct and safer choice.

Another issue occurs when very hard grinding wheels are used on thin or flexible workpieces. In these cases, the wheel tends to generate heat faster than it removes material. Operators may experience glazing, poor cutting response, and a need to apply more pressure, which further reduces control and consistency.

Grinding wheels are also not well suited for low-power angle grinders when aggressive abrasives or very hard bonds are selected. In such setups, the wheel cannot self-sharpen properly. Instead of cutting efficiently, it rubs against the surface, producing vibration and uneven wear. This is often misinterpreted as a quality issue, while the real cause is a mismatch between wheel design and operating conditions.

In real applications, choosing the wrong grinding wheel usually does not fail immediately. Problems build up gradually in the form of heat accumulation, unstable handling, and operator fatigue. For this reason, selecting the correct tool and specification is often more important than selecting the hardest or most durable wheel.

How to select the correct grinding wheel

Selection should start with the application:

-

Carbon steel grinding generally works well with aluminum oxide

-

Stainless steel benefits from white aluminum oxide or optimized zirconia formulations

Wheel thickness and diameter should match the tool and intended grinding pressure. Thinner wheels offer better control, while thicker wheels provide higher stability for heavy grinding.

Operating speed and machine compatibility must always be verified to ensure safe use.

| Application | Material Type | Recommended Grinding Wheel | Benefit |

|---|---|---|---|

| Weld seam grinding | Carbon & low-alloy steel | Type 27 aluminum oxide wheels | Stable contact, fast removal |

| Surface prep | Stainless steel | White aluminum oxide wheels | Reduced heat buildup |

| Heavy grinding | Cast iron, high alloy | Zirconia alumina wheels | High stock removal |

OEM customization and manufacturing responsibility

Professional grinding wheel manufacturers offer OEM customization options such as:

-

Abrasive formulation adjustment

-

Wheel hardness tuning

-

Thickness and diameter customization

-

Arbor size options

-

Label and packaging design

At the same time, responsible manufacturers maintain clear technical limits. Certain combinations of parameters may be declined if they compromise safety or performance.

This balance between flexibility and responsibility is an important indicator of manufacturing quality.

Industry standards and compliance

Grinding wheels are manufactured in compliance with recognized safety standards such as EN12413 for bonded abrasives. Compliance ensures minimum safety performance under rated operating conditions.

Standards compliance should be considered a baseline requirement rather than a differentiating feature.

Grinding wheels are engineered tools that must balance cutting ability, durability, safety, and operator control. Their performance in real use is determined by manufacturing decisions made long before the wheel reaches the user.

For buyers and distributors, understanding these fundamentals allows more informed product selection and supplier evaluation. A reliable grinding wheel supplier is not defined by product claims alone, but by consistent manufacturing quality and practical application knowledge.

Special Line SG-PLUS (Reinforced Grinding Wheels)

-

For Steel

- Abrasive: Aluminum Oxide A

- Hardness: R (Very hard)

- Applications: Weld-seam chamfering, deburring, heavy-duty surface grinding

- Features: Outstanding cutting performance, exceptional tool life, optimized for high-powered air and electric angle grinders

-

For Stone & Cast Iron

- Abrasive: Silicon Carbide C

- Hardness: R (Medium-hard professional tool)

- Applications: Cutting and grinding of natural and synthetic stone, fire-resistant stone, cast iron, hard aluminum

- Features: High lateral stability, long service life, suitable for angle grinders and high-frequency grinders

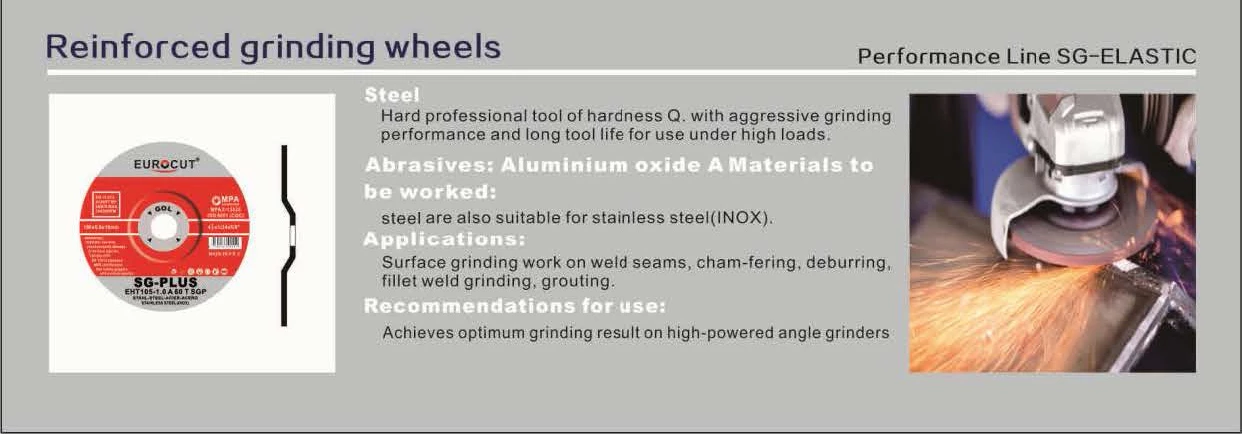

Performance Line SG-ELASTIC (Reinforced Grinding Wheels)

- Abrasive: Aluminum Oxide A

- Hardness: Q (Hard professional tool)

- Materials: Steel and Stainless Steel (INOX)

- Applications: Surface grinding on weld seams, chamfering, deburring, fillet-weld grinding, grouting

- Features: Aggressive grinding under high loads, long tool life, excellent vibration absorption

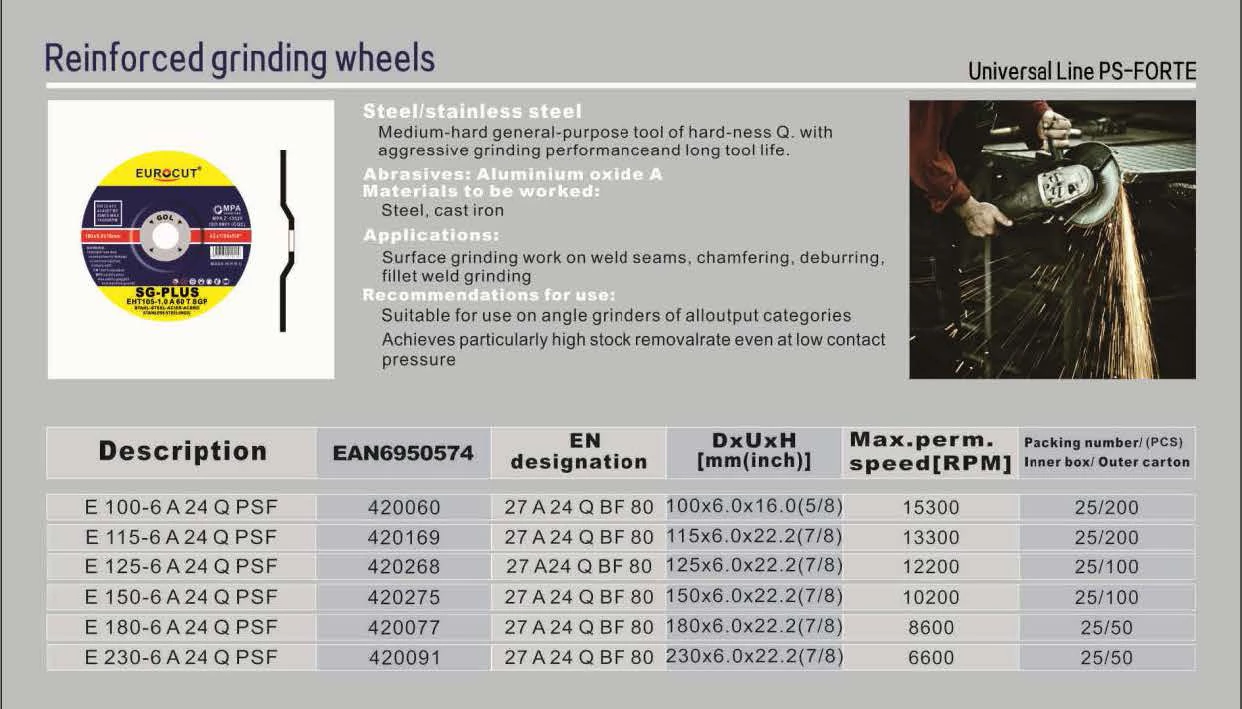

Universal Line PS-FORTE (Reinforced Grinding Wheels)

- Abrasive: Aluminum Oxide A

- Hardness: Q (Medium-hard general-purpose)

- Materials: Steel, Cast Iron

- Applications: Surface grinding, chamfering, deburring, fillet weld finishing

- Features: Well-balanced cutting performance, long life, high stock removal even at low contact pressure

Why Choose Us

-

Improvements on proven and reliable products, maximizing your tool efficiency.

-

Precision grinding, ensuring a scratch-free surface on your workpiece.

-

Significantly extended tool life, tested in real-world applications.

Why Trust Qing Yang

Qing Yang is our carefully developed private brand, dedicated to offering a wide range of high-performance, high-quality, and cost-effective abrasive products. This is not just a slogan—we hold the MPA-CERTIFICATE, the highest-level certification for grinding products worldwide, which reflects our strong commitment to safety, performance, and consistency.

Every Qing Yang abrasive tool meets strict ISO 9001 standards. Each production batch undergoes rigorous testing for bond strength, grain retention, and dimensional accuracy, ensuring a traceable manufacturing process and uncompromising quality control.

Our products are trusted and favored by buyers and engineers in more than 50 countries and regions around the world. By working with us, you gain access to top-quality grinding wheels and discs backed by the industry’s highest certifications.

Choosing the right grinding wheel for your job

Wheel hardness, grain type, and thickness all affect performance under load. These guides explain how to match specifications to your actual grinding conditions.

Choosing Grinding Wheels for Weld Removal

Grain type, bond hardness, and disc thickness — matched to weld profile and material.

Grinding Wheels vs Flap Discs

Structural design, load behavior, and when each tool belongs in the process sequence.

Why Grinding Wheels Fail Prematurely

Application errors vs. manufacturing defects — root cause analysis for production environments.

Sizes of Grinding Wheels

| MM | INCH | SPEEDR.P.M | SPEEDM/S | PCS/CTN |

| 100X4.0X16 | 4×1/8×5/8″ | 15200 | 80 | 300 |

| 100X6.0X16 | 4×1/4×5/8″ | 15200 | 80 | 200 |

| 115X6.0X22.2 | 4 1/2×1/4X7/8″ | 13300 | 80 | 200 |

| 125X6.0X22.2 | 5×1/4×7/8″ | 12200 | 80 | 100 |

| 150X6.0X22.2 | 6×1/4×7/8″ | 10200 | 80 | 100 |

| 180X6.0X22.2 | 7×1/4×7/8″ | 8500 | 80 | 50 |

| 230X6.0X22.2 | 9×1/4×7/8″ | 6640 | 80 | 50 |

Customized Grinding Wheel Services

Renowned grinding wheel manufacturer Qing Yang not only produces products under its own brand, but also offers comprehensive OEM/ODM customization solutions for grinding wheels. Our customized products meet the most demanding requirements in the global grinding industry, with certifications reaching up to the prestigious MPA-CERTIFICATE level.

Flexible Size Customization

We offer highly flexible size specifications:

-

Outer diameter: A wide range is available, from compact 3-inch wheels to large 9-inch heavy-duty wheels, all customizable to your requirements.

-

Inner diameter: Customizable as well (e.g., standard sizes like 16mm, 22.2mm, 25.4mm, or special dimensions to suit your equipment).

-

Thickness: Precisely controlled to meet various grinding intensity demands across different applications.

Optimized Materials & Performance

Our engineering team tailors the abrasive composition and bonding agent ratios based on your specific application—whether it’s metalworking, stone processing, or general-purpose grinding.

Utilizing advanced technologies like anti-static treatment and heat-resistant coatings, our customized grinding wheels can match the performance of leading industry brands such as Norton and Klingspor.

Build Your Own Brand

Looking to establish your own brand? We offer full-service customization, including:

-

Custom label printing

-

Color-coded grit identification system

-

Exclusive product data sheets

We cover a wide range of grinding wheels, including:

-

Standard angle grinder wheels

-

Heavy-duty grinding wheels

Whether based on your existing samples or technical drawings, we can develop tailor-made grinding wheels for you. We also support mass production replication, performance optimization, and small batch samples for feasibility testing.

Quality Assurance

All custom grinding wheels are manufactured under a strictly enforced quality control system and ultimately certified by MPA, ensuring full compliance with international safety and performance standards.

Start your customized

Start your customizedWhat happy customers have to say

- Business Development Manager

Frequently Asked Questions (FAQs)

Grinding wheel basics

Q: What is a grinding wheel?

A: A grinding wheel (also called a polishing disc) is a disc-shaped grinding tool that is made of sharp abrasive particles bonded by a resin binder. Qing Yang uses a variety of abrasive formulas according to different operating scenarios, and all products are compatible with standard angle grinder interfaces. The reinforced grinding wheel embeds multiple layers of high-strength fiberglass mesh in the resin layer, which can increase the service life by 50% and ensure structural stability under extreme working conditions.

Q: What are the main uses of grinding wheels?

A: The core functions cover five major areas:

- Metal surface treatment (rust removal/weld scar cleaning)

- Industrial burr removal

- Automotive sheet metal repair

- Concrete substrate pretreatment

- Rapid material removal (such as steel structure cutting)

Innovative application: Our 1/8 inch (about 3.2mm) hybrid grinding disc can complete cutting and rough grinding at the same time, reducing tool replacement time by 70% in steel bar/metal pipe operations.

Model and technical parameters

Q: What is the difference between T1 and T27 grinding wheels?

| Model | Structural features | Applicable scenarios |

|---|---|---|

| T27 | Center concave plane | Conventional plane grinding |

| T29 | Curved surface convex design | ≥45° inclination operation |

| T1 | Fully flat double-sided structure | Dedicated for cutting discs/bench grinders |

Q: How to choose abrasive materials?

A: Recommended solutions based on metal characteristics:

- Aluminum oxide: Black metals such as carbon steel/stainless steel (resistant to high temperature sintering)

- Silicon carbide composite formula: Dedicated for soft metals such as aluminum/copper (patented anti-blocking technology)

Technical breakthrough: Qing Yang soft metal grinding wheel adopts low-temperature grinding process, which can reduce the temperature rise of the workpiece by 65% through pressure sensor control.

Safety Operation Guide

Q: Can grinding wheels and cutting discs be used together?

A: Absolutely prohibited! The essential differences are as follows:

| Tool type | Thickness range | Functional positioning | Risk warning |

|---|---|---|---|

| Grinding wheel | 1/4 inch (6.4mm) | Surface grinding | Cutting operation may cause bursting |

| Cutting disc | ≤3/32 inch (2.4mm) | Material splitting | May disintegrate in layers during grinding |

For a full explanation of structural differences and why substitution is unsafe:

Q: What are the iron rules for safe operation?

A: 10 major guidelines must be followed:

- Triple protection: mask + anti-cut gloves + noise-reducing earmuffs

- Pre-start inspection: Cracked/defective grinding wheels must be scrapped immediately

- Power matching: angle grinder rated power ≥ grinding wheel requirements

- Protective cover disabled: It is strictly forbidden to remove or modify protective devices

- Speed control: equipment no-load speed ≤ grinding wheel red line mark

- Start-stop specification: start idling for 30 seconds → operation → complete stop before leaving

- Operating posture: hold with both hands + stable standing posture

- Dress requirements: tight work clothes + hair tie (to prevent entanglement)

- Regular maintenance: check the status of the motor carbon brush every shift

- Emergency preparation: configure fire extinguishing equipment within the operating radius of 3 meters

See also: failure patterns caused by common operating errors:

Purchasing Guide

Q1: What is the production lead time?

A:

- Standard sizes are in stock and can be shipped within 3 days .

- For non-standard or customized products, the production lead time is approximately 30–40 days .

Q2: Are you a factory or a trading company?

A: We are a professional manufacturer of abrasive tools with over 35 years of experience.

Q3: Do you accept OEM branding?

A: Yes, OEM branding is available . We can also provide free label design services.

Q4: Are samples available for quality testing?

A: Yes, free samples are available for quality testing. However, the shipping cost is borne by the customer.

Q5: Do you have any certifications?

A: Yes, we are certified with MPA and ISO standards.

Q6: How long is the delivery time?

A: Normally, delivery takes about 20 days after receiving payment .

Grinding Wheel Application Guides

Selection guides, failure analysis, and safety boundaries — all specific to grinding wheel applications in metal fabrication.

Selection & Application

Match wheel spec to your material removal requirementsChoosing Grinding Wheels for Weld Removal

Grain type, bond hardness, and disc thickness for heavy weld grinding.

→ ComparisonGrinding Wheels vs Flap Discs

Why these tools operate in sequence, not as substitutes.

→ Failure AnalysisWhy Grinding Wheels Fail Prematurely

The application errors that cause most premature failures.

→Safety Boundaries

Tool substitution errors that affect grinding wheel operationsCommon Abrasive Tool Selection Mistakes

How using cut-off wheels for grinding and other load-direction errors cause failure.

→ BoundaryWhy Flap Discs Should Not Replace Grinding Wheels

Structural reasons why flap discs lose efficiency under heavy grinding load.

→ ComparisonCut-off Wheels vs Grinding Wheels

Load direction, structural design, and why they cannot substitute for each other.

→