Ever stared at a wall of cutting discs at the hardware store, feeling that familiar brain fog kick in? Yeah, decision fatigue hits hard when you’re just trying to slice through some steel without turning your project into a headache. If you’re tackling metal cuts—whether it’s rebar, pipes, sheet stock, or stainless sheets—we’ve got your back. In this guide, we’ll zero in on the best cutting discs for metal, breaking down options that match your job, tool, and budget. From angle grinders to chop saws, we’ll help you pick the right one so you cut clean and stay efficient.

One quick heads-up before we gear up: Safety isn’t optional here. Dust and sparks fly fast with metal work, so gear up with a solid respirator (like an FFP3 or one with P3 filters), impact-rated goggles, cut-resistant gloves, and ear protection. It keeps the fiberglass shards, metal filings, and fumes from messing with your day. We’ll touch on it where it fits, but consider this your one-and-done reminder: Protect yourself first.

Best Overall Cutting Disc Brand for Metal

Brands can feel like a loyalty test in the abrasive world—do you chase the shiny new name or stick with a proven player?

Hands down, DeWalt edges out as the top pick for metal cutting across the board.

Their discs blend speed, longevity, and versatility, handling everything from mild steel to tougher alloys without skipping a beat. Take the DeWalt 4-1/2 in. x 0.045 in. Metal/INOX Cutting Wheel—it’s a beast for stainless and ferrous metals, with an aluminum oxide grit that chews through without excessive heat buildup. Or their HP premium line for heavier jobs.

Why DeWalt? Tests show they outlast generics by up to 75% on tough cuts like black pipe, making them a smart everyday go-to.

Best Cutting Disc for Stainless Steel

Stainless is finicky—it’s tough, but heat can warp or discolor it if your disc isn’t spot-on. Go for iron-free options to avoid contamination; aluminum oxide or zirconia alumina abrasives shine here, as they cut cool and clean. Thinner discs (1mm or less) minimize burrs and friction, perfect for sheets or tubes.

A standout is the Bosch Professional INOX Cutting Disc (125mm x 1mm). It’s engineered for stainless with a high-performance bond that resists clogging, delivering precise, burr-free edges on profiles or sheets. Users rave about its longevity—up to 50% more cuts than standard discs—without the blue tint from overheating. If you’re on a chop saw, pair it with lubricant for even smoother runs.

Best Cutting Disc for Mild Steel

Mild steel is forgiving for most DIYers, but you want a disc that powers through without bogging down your grinder. Aluminum oxide rules for ferrous metals like this—it’s aggressive yet durable, ideal for structural beams or exhaust work.

The Lenox MetalMax3 (4-1/2 in. x 0.040 in.) is my top rec here. Diamond-infused edges give it insane life—over 500 cuts on rebar or angle iron—while staying thin for quick plunges. It’s a game-changer for welders tackling frames or repairs, cutting vibration and dust compared to traditional abrasives. Pro tip: For thicker stock (over 1/4 inch), bump to 1.6mm thickness to handle the torque without flexing.

Best Cutting Disc for Aluminum

Aluminum’s lightweight champ status comes with a catch: low melt point means it gums up discs fast if you’re not careful. Opt for silicon carbide abrasives—they resist loading and stay sharp on softer non-ferrous metals. Thinner profiles (0.8-1mm) cut heat, and a touch of cutting wax extends life.

Benchmark Abrasives’ Type 1 Thin Cutting Wheel (4-1/2 in. x 1/16 in.) nails it, blending silicon carbide and aluminum oxide for clean slices on extrusions or panels. It lasts through dozens of sessions without clogging, and the fiberglass reinforcement adds burst resistance for peace of mind. Avoid pushing too hard—let the disc do the work to dodge melting edges.

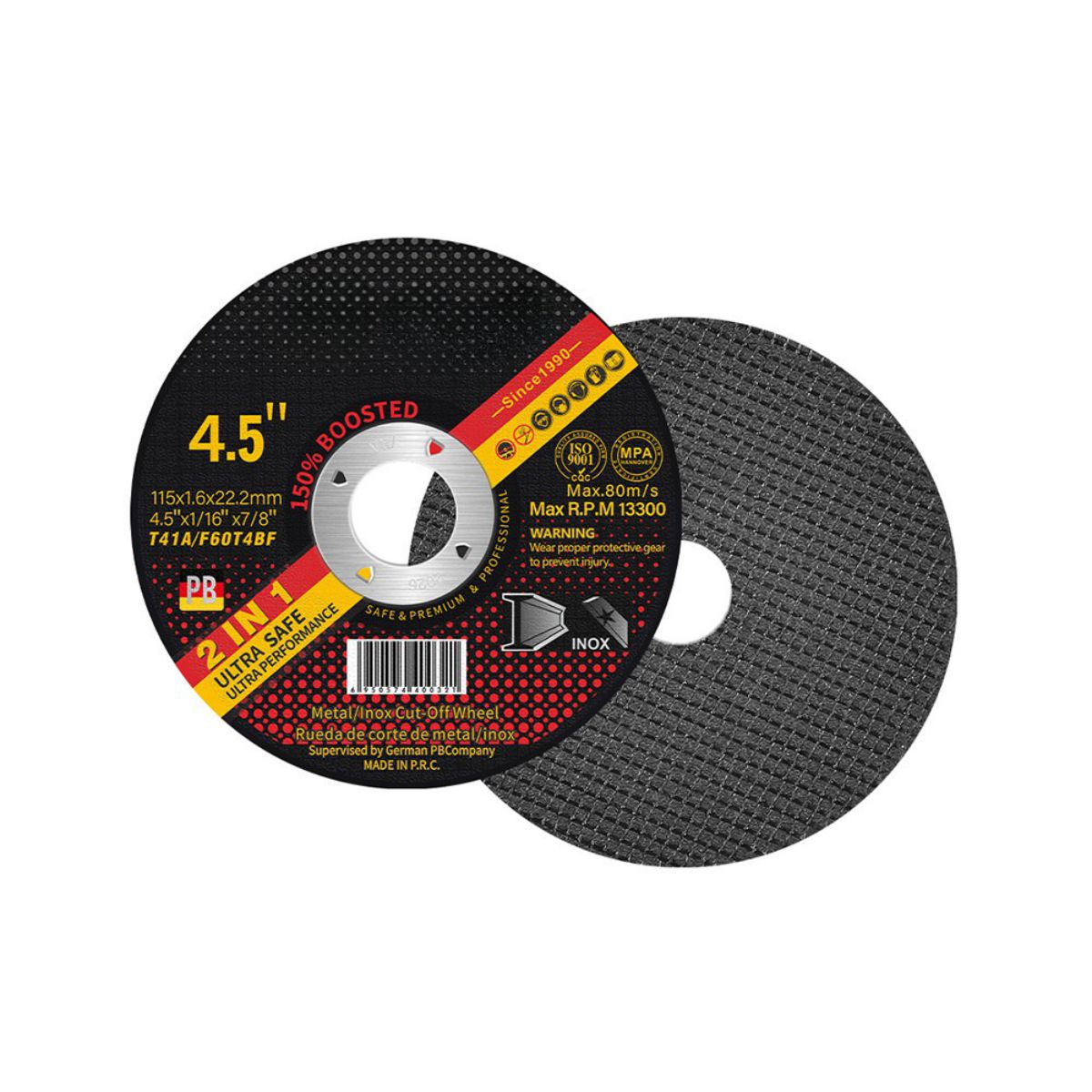

Best Cutting Disc for Angle Grinders

Angle grinders are the workhorse for on-the-go metal cuts, so your disc needs to match the RPM (aim for 13,000+ rated) and arbor size (usually 7/8 in.). For metal, 4-1/2 in. diameter with 1mm thickness is versatile—fast on thin stock, stable on pipes.

The Makita Premium Thin Cut-Off Wheel (4-1/2 in. x 0.040 in.) is unbeatable for grinders. Its resin bond and aluminum oxide matrix slice steel or stainless effortlessly, with minimal kickback. Great for fab shops or garages, it handles wet or dry cuts and outperforms on speed tests. If you’re multi-material, their hybrid versions tackle light alloys too.

To help compare these recommendations side-by-side, here’s a table summarizing the top picks by category:

| Category | Recommended Product | Key Specs | Best For | Abrasive Type |

|---|---|---|---|---|

| Overall Best Brand | DeWalt 4-1/2 in. x 0.045 in. Metal/INOX | 4-1/2″ dia, 0.045″ thick | Stainless & ferrous metals | Aluminum oxide |

| Stainless Steel | Bosch Professional INOX (125mm x 1mm) | 125mm dia, 1mm thick | Sheets & tubes | Zirconia alumina |

| Mild Steel | Lenox MetalMax3 (4-1/2 in. x 0.040 in.) | 4-1/2″ dia, 0.040″ thick | Rebar & angle iron | Diamond-infused |

| Aluminum | Benchmark Abrasives Type 1 Thin (4-1/2 in. x 1/16 in.) | 4-1/2″ dia, 1/16″ thick | Extrusions & panels | Silicon carbide + Al oxide |

| Angle Grinders | Makita Premium Thin (4-1/2 in. x 0.040 in.) | 4-1/2″ dia, 0.040″ thick | Steel & stainless | Aluminum oxide |

Key Factors to Consider When Choosing a Cutting Disc

Picking the right disc boils down to a few no-brainer checks—get these right, and you’ll avoid half your headaches. Start with material match: Aluminum oxide for steel/stainless, silicon carbide for aluminum. Thickness matters—thin (under 1.2mm) for speed on sheets, thicker (1.6mm+) for heavy beams to reduce wobble.

Grain size (60-80 for general metal) affects aggression, while bond type (resin for flexibility) ensures safety. Size to your tool: 115mm for compact grinders, 230mm for big saws. And always eyeball the EN12413 safety rating—it’s your assurance against shards.

Top Budget-Friendly Cutting Discs for Metal

Who says quality has to drain your wallet? Smart buys keep you cutting without compromise. Look for packs from trusted lines—value packs stretch your dollar.

The SATC Ultra Thin Metal Cutting Discs (115mm x 1mm, 20-pack) are a steal at under $20, zipping through steel and iron with zirconia edges for extra grit life. They match pricier options on thin cuts, though swap ’em sooner on thick jobs. For a step up, WORKPRO’s 20-pack (115mm) handles stainless on the cheap, with solid reviews for garage warriors.

Here’s a comparison table for budget options:

| Product | Pack Size | Price Range | Key Features | Best For |

|---|---|---|---|---|

| SATC Ultra Thin (115mm x 1mm) | 20-pack | Under $20 | Zirconia edges, fast cuts | Steel & iron thin cuts |

| WORKPRO (115mm) | 20-pack | $15-25 | Durable for stainless | Garage & DIY stainless |

| Harbor Freight Warrior Ultra Thin | 10-pack | Under $15 | Tough edges, extra life | General steel & iron |

Premium Picks for Professional Use

If you’re in it daily—welding shops or fab crews—invest in discs that pay off in time saved. Premium means better grains, bonds, and reinforcements for 2-3x the cuts.

Walter’s Zip-Cut discs top the list: Their 4-1/2 in. stainless version lasts forever on high-RPM grinders, with minimal dust and zero flex. Or 3M Green Corps—pricey but unbeatable for speed on titanium or alloys, per welder forums. These aren’t for one-offs; they’re for pros chasing efficiency.

For pros, this table breaks down premium choices:

| Product | Key Specs | Advantages | Best For |

|---|---|---|---|

| Walter Zip-Cut (4-1/2 in.) | Stainless version, high RPM | Minimal dust, long life | High-volume grinding |

| 3M Green Corps | For titanium/alloys | Superior speed | Alloys & tough metals |

| Diablo DBD090094101F | Al oxide blend, reinforced | Extra-long life | Hand-held heavy cuts |

How to Maintain and Store Your Cutting Discs

A good disc deserves care—mishandle it, and you’re back to square one. Store in a dry, cool spot away from moisture (rust kills abrasives fast), and use original packaging to prevent edge chips. Inspect before each use: Dings or cracks? Toss it. Mark dates on packs to rotate stock—fresher discs cut truer.

For longevity, clean off residue post-job with a soft brush, and avoid dropping tools. Proper habits can double your disc life, saving cash and hassle.

FAQs

What’s the difference between aluminum oxide and silicon carbide cutting discs?

Aluminum oxide is aggressive for hard ferrous metals like steel, while silicon carbide excels on softer non-ferrous ones like aluminum without clogging.

Can I use the same disc for metal and wood?

Nope—metal discs spark and overheat wood. Grab a dedicated multi-material like diamond-edged for versatility, but always match to your primary job.

How thin is too thin for a cutting disc on thick metal?

Under 1mm risks shattering on anything over 2mm thick. Stick to 1.6mm+ for beefy cuts to keep things safe and steady.

Are diamond cutting discs worth it for metal?

Absolutely for longevity—EZARC’s model hits 5,000+ cuts on rebar. They’re pricier upfront but save time on repetitive fab work.

What if my disc vibrates during use?

Check alignment and RPM match first. If it’s warped, replace it—vibration leads to uneven cuts or worse, breaks.